Heating with wood pellets: the question to ask before choosing this method of heating?

What pellet tonnage will be needed? See also pellets consumption calculation?

Home pellet silo

Once you have your annual heat balance you can deduct the necessary pellet tonnage and thus the volume of your silo.

a) starting from the thermal balance

Your heat balance gives you an annual useful energy requirement expressed in kWh.

Each kg of granules contains between 4,5 and 5kWh. Take 5kWh which corresponds to German standards.

So just divide your annual energy requirements in kWh by 5 to find your pellets needs in kg.

Also correct and divide by the average efficiency of your boiler, take 90% yield.

Example: a modern well-insulated house of 150 m² needs 100 kWh / m².year 150 000 kWh per year. Boiler with a yield of 90%.

This makes 15000 / (5 * 0,9) = 3333 kg or 4 Tonnes on delivery (most suppliers deliver per tonne).

ps: beware your heat balance may have already taken into account your boiler performance. In this case the correction of the 0.9 is to be deleted.

(b) from the consumption of fuel oil or gas

Here too it is quite simple: 2 kg of Pellets = 1 L of fuel oil = 1 m3 of gas.

So if your house used 2000L fuel, you would need 4000 kg of Pellets.

A correction is also to be made in terms of the efficiency of the boiler. But this also depends on the performance of your old boiler.

So if you had a boiler that was about 30 years old, we can estimate the efficiency to be 70%. The efficiency of your new boiler being 90%, you will consume less gross energy for the same useful energy.

So let's take the 2000L of gross energy, i.e. 20 kWh: it therefore corresponded to 000 kWh (= 14 * 000) of useful energy, or 20 kWh (= 000 / 0,7) of gross energy in your new boiler. 15% yield or 555 kg of Pellets.

What volume of silo is needed?

The density of the bulk pellets is between 650 and 750 kg / m3. Take 700 kg / m3. The necessary tonnage divided by 0,7 therefore gives the necessary silo volume.

Take 10 security at 15% for dead volumes.

Example: 4 Tonnes of Pellets therefore require: (4 / 0,7) * 1,15 = 6.57 m3 is 7m3.

Another method: starting from your tank of oil, for example 2000L it is necessary to multiply by a coefficient of 3,5.

Technological aspects of the silo

The extraction of the silo is done either by an endless screw, or by suction mouths following the marks.

If the extraction is done by screw, it is necessary to learn about the standard lengths of screws in order to adapt.

a) Screw feeding

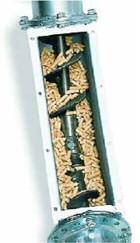

Archimedean screw for automatic feeding of a pellet boiler

The internal length of the silo will be superior from 20 to 60 cm to the screw length.

The internal width of the silo must be limited to properly feed the screw (1,5 to 1,8 m max).

Silo hopper not required

Contrary to what the manufacturers recommend, I recommend not to make a floor in the form of a hopper. It's complicated if you want to make it solid (it must withstand several tons of pellets!) So it quickly becomes expensive and ultimately does not help much: if not to empty your silo 100% and it is it obviously illusory to want to empty your silo down to the last pellet before having it refilled?

However, if possible, think about emptying it completely every 2 refills so that the “stagnant” pellets are consumed. Indeed, after 2 years and depending on the humidity conditions, the pellets may lose their quality (increase in humidity and therefore consumption and polluting emissions of unburnt particles).

I recommend a flat floor at the height of the screw (22mm chipboard false floor on 5cm rubble stone laid flat). In this case, two “triangles” of granules will never be consumed. This is your "reserve" (as on motorcycles): if you ever reach the end of the silo and forget to have it filled. In this case, you enter your reserve, give a few blows of the shovel to collect the pellets on the screw while awaiting delivery (note: sometimes several weeks delay).

Homemade pellet silo: “foundations” of the silo.

The silo will be built in rubble of 10 cm, with an access door opening to the outside of the silo with a seal to avoid dust during filling.

Homemade pellet silo: “door” to the outside.

Inside side of the opening, it is necessary to put two angles allowing to insert boards (thickness 27mm) of retention of the pellets. To find out what's left in the silo, I recommend a window on one of the top boards. It is necessary to think about the filling orifice and the air outlet (supplied with the boiler), situated on the same side of the silo.

There is also a rubber mat, attached free to the ceiling in front of the filler hole, to prevent the pellets from splashing on sawdust on the opposite wall during filling. Be careful not to have any water pipes or electrical conduits that pass inside the silo.

In the event of a silo inside the house, take maximum care in its construction to prevent parts of the silo from rubbing either between them or against the walls. Indeed, during the operation of the feed screw, the silo can vibrate and resonate throughout the house!

Homemade pellet silo: filling and aeration mouth. Be careful, this mouth must be outwards only otherwise there is a high risk of dust throughout the cellar when filling. Find out, your pellet supplier may be a double pipe system that also sucks up dust (a bit like refueling circuit cars).

In order to avoid the capture of humidity from the air (hygroscopicity) the silo must be as tight as possible with exterior air currents, the walls of the recess will be previously treated against humidity or covered with a panel.

Depending on your location, your boiler is immediately adjacent to the silo or not. If this is the case, the auger can directly feed the boiler hopper. This is the solution that is recommended but not possible all the time, in this case it is necessary to have recourse to a suction system!

b) Suction feeding

If your silo is far from the boiler, you can opt for transport by suction directly from inside the silo. However, even in this case the maximum length of the suction is 20m and 6m high!

You then have a suction turbine (it's a big 1000 vacuum cleaner with about 1400 W of motor) and two flexible pipes of 60mm diameter between the silo and the boiler hopper. The turbine circulates the air at high speed in this loop back and forth, which causes the granules to pass.

On the boiler side, the flow goes into a cyclone where the granules slow down and then fall into a hopper, while the air is re-sucked into the 2eme tube. One can even go up one floor, and make a maximum length of about twenty meters.

Suction pellet feeding

In this case, the boiler has a hopper reserve of about 1 heating day to avoid calling pellet from the silo too often. The suction turbine is quite noisy.

We schedule what time we want the filling of the hopper, it prevents it from happening in the middle of the night. The filling only lasts a few minutes.

Important, the trap of static electricity: compulsory earthing!

The friction of dry pellets generates static electricity.

It is imperative to ground the filling ports as well as the silo-boiler pipes, whether with a screw feed but especially with a suction feed where the effect of air friction is further increased.

Indeed: the dust from the pellets can be flammable (remember that the first diesel engines worked… with coal dust!) And a spark in the air can therefore ignite this dust!

Earthing of all the metal parts of the room is therefore more than recommended! The risk is not very important but it exists all the same!

Read more: hot water ECS and wood boiler or pellet

Previous article: Pellet consumption estimate calculation

hello I have a small problem with my pellet suction system I seem to go up 50cm in my pellet sink by the endless screw. then the sawdust clogs the first 2 pellet exits would you have an answer to this problem?

Good evening very nice page, may it get the suction turbine please. cordially

Good evening very nice page, but where to get the suction turbine please? And the fire brigade fittings for delivery? Sincerely thank you g lejay