The treatment of motor vehicle end of life

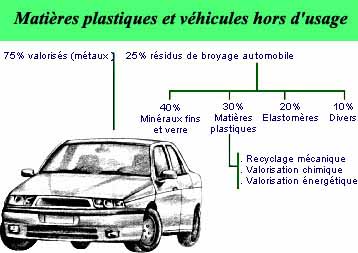

After use, motor vehicles are shredded with household appliances and demolition scrap for the recovery of metals. This operation generates Crushing Residues (RB). About 25% of the initial weight of a vehicle is found in these RBs, of which a third is plastic. These BRs were previously landfilled. This solution is no longer acceptable now.

To solve this problem, all the industrialists of the French automobile sector, supported by the Ministries of Industry and the Environment, signed on March 10, 1993 a Framework Agreement, according to which they undertook to gradually reduce the quantities of waste landfilled. The objective is to reduce the current percentage of 25% of the weight of end-of-life vehicles, to 15% in 2002, then 5% in 2015.

To do this, a four-phase treatment plan for ELVs (end-of-life vehicles) has been established:

- Pre-treatment: vehicle safety (airbags, etc.), pollution control (batteries, oil, coolant, brake fluid, fuel, windshield washer fluid, etc.)

- Dismantling: selection of parts for reuse (eg Starter) or for the recycling of materials (eg PP in the bumper or PVC coverings for seats and dashboards)

- Crushing: recovery of ferrous and non-ferrous

- Treatment of RBs: material recovery from mineral residues (glass, etc.), energy recovery from remaining organic materials (rubbers, etc.) or, in the future, chemical or mechanical recycling.

In Europe, the Directive of the European Parliament and of the Council relating to end-of-life vehicles (Directive 2000/53 / EC, OJ of 21/10/2000 L 269/34) specifies in article 7.4 that approved vehicles, in accordance with to Directive 70/156 / EEC and placed on the market from a date not later than 01/01/2005 must be reusable and / or recyclable at least at 85% by weight of the vehicle and must be reusable and / or recoverable at a minimum of 95% by weight per vehicle.

There is no systematic hierarchy in the waste recovery options. Each situation must be examined on a case-by-case basis to define the best recovery solution. Schematically, the distribution of 100 kg of plastic parts present in end-of-life vehicles (1990 models) allows the following options:

- # 20 kg approximately for 10 large parts (bumpers, door panels, seat and dashboard coverings, fuel tanks, etc.): mechanical recycling after dismantling is the desirable recovery option.

- 80 kg representing 1500 pieces of approximately 50 g: these parts are generally too small to be dismantled and recycled. Another type of valuation must be sought.

In the latter case, energy recovery is the preferable waste management option, because for very small parts, the disassembly time is too long for recovery by mechanical recycling to be economical. The cost of dismantling labor actually exceeds the value of the materials recovered.

Recycling is all well and good, but above all we have to change the paradigm concerning the car. We must combine all kinds of soft mobility and abandon the personal car