I am new to this forum, I find the site very interesting and enriching, I learned a lot, but I need advice on my case ... thank you for reading me

Here, I bought a house at the end of December equipped with central heating by wood pellet boiler. The former owner explained to me the operation, the maintenance and gave me the instructions, everything works. But given the different topics, I think there are things to improve. You tell me ...

Here is the detail :

House Year 1983 of 120m2 on 2 floors: concrete block + glass wool + plastered brick.

Central heating was installed less than 5 years ago in place of electric convectors. There is also a fireplace with insert.

The boiler is installed in a shelter about 20 meters from the house:

Pellets are stored in the open room next to the boiler:

The boiler is an HS Tarm MultiHeat 2.5

The water temperature is set to 80 °

There is a circulator at the outlet of the boiler. The circuit goes under the courtyard, the pipes are well insulated according to the former owner (I trust)

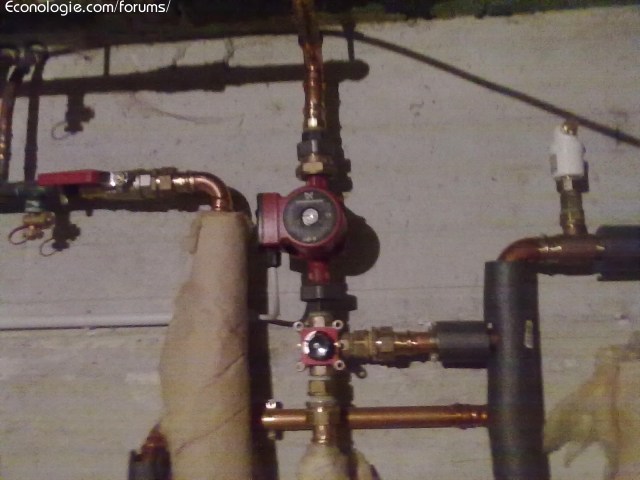

It happens in my cellar, where there are 2 other circulators and the hot water tank that goes electric in summer. Then the adjustment is made by an adjustable valve from 0 to 10 which is very sensitive, the slightest angular degree changed greatly varies the degrees celsius in the house.

I am on 2 and it is on average 23 ° in the house.

Then, there are 4 radiator circuits in the house equipped with simple taps:

Well, sorry for the poor quality of the photos.

* The previous owner spent around 3 Tons of pellets until the end of December, is that a lot? I brought in 3 more, that will make 6 Tons in all.

* Is it useful to put thermostatic valves on my radiators (all?)

* Should the water temperature leaving the boiler be lowered? 80 ° is the T ° noted on the boiler manual ...

* Can I close several radiators without worries?

* Is it possible to put a thermostat which controls this valve or another?

* Should we close the silo completely, can it improve performance? Maybe the pellets get wet? I plan to do it in the spring anyway.

Thank you in advance