Hello Pitmix, André and the others

Apparently my message yesterday was lost, I did not understand why. I had to do the ball with a command ?!

It's nice to interest you in my scheme.

Some info, to try to be clearer:

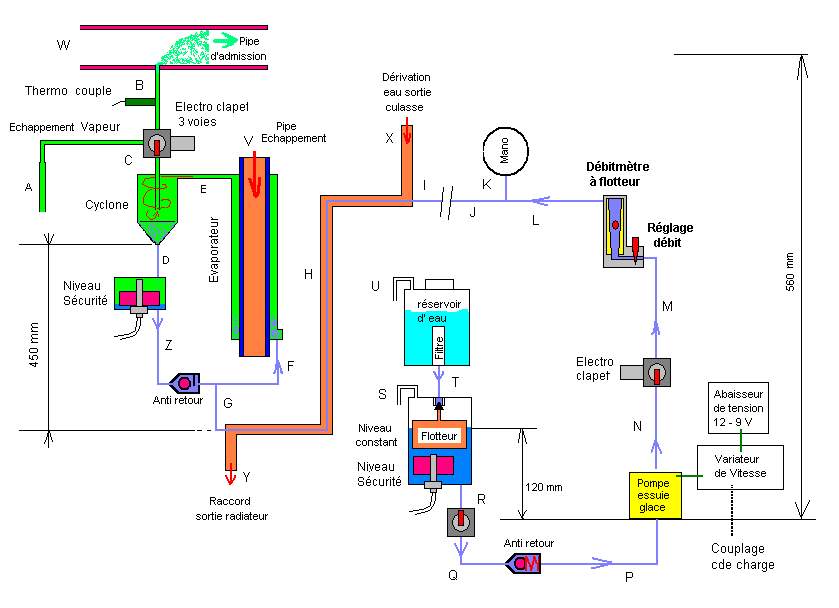

The basic idea is to make a GV the most responsive possible, 'able' to follow the needs of the engine when the load varies. So I chose a volume of water to heat low (1 / 4 1 / 2 liter?).

To further improve the reactivity, the GV consists of 4 6 / 8 mm copper pipes directly brazed externally, on the exhaust handlebar. (The heating area is very large compared to the volume of heated water). Finally, the water that reaches the SG is preheated with a bypass of the cooling circuit. (70 °?).

When the car returns to idle, the skin temperature of the exhaust drops to <100 ° in just a few seconds. There are therefore very few calories available to evaporate the water in the SG. So if the water is already hot, we will keep the production of steam 'a little longer'. Hot water is easier to evaporate than cold water).

Ideally, when the load is medium or high, the water vaporizes almost instantaneously by entering the GV and the volume of water in the pipes is very low and therefore the response is 'instantaneous' to the flow control settings. water. (If it does, I'm not saying conn .....)

For the cyclone, in my preliminary tests, I heated my copper pipes 6 / 8 mm by blow molding more or less 'abruptly' with water. On the other side he often comes out a violent puff of steam which leads with it full of big drops of water. This operation seemed to me too unstable and it seemed important to me never to send water in 'package' in the engine.

An anecdote, I saw a diesel engine with the cylinder head gasket that pissed the cooling water in the combustion chamber (for too long). Result, a breech riddled with dozens of holes (detonation) with a kind chocolate mousse appearance but more indigestible breech and dead piston.

André, I agree with you, I could have done much simpler and I have no guarantee or certainty for that my editing will work (especially the first time). But the pleasure of mechanics does not count ... For the time, the place and the equipment to put it all in focus, I think not be better off than the others.

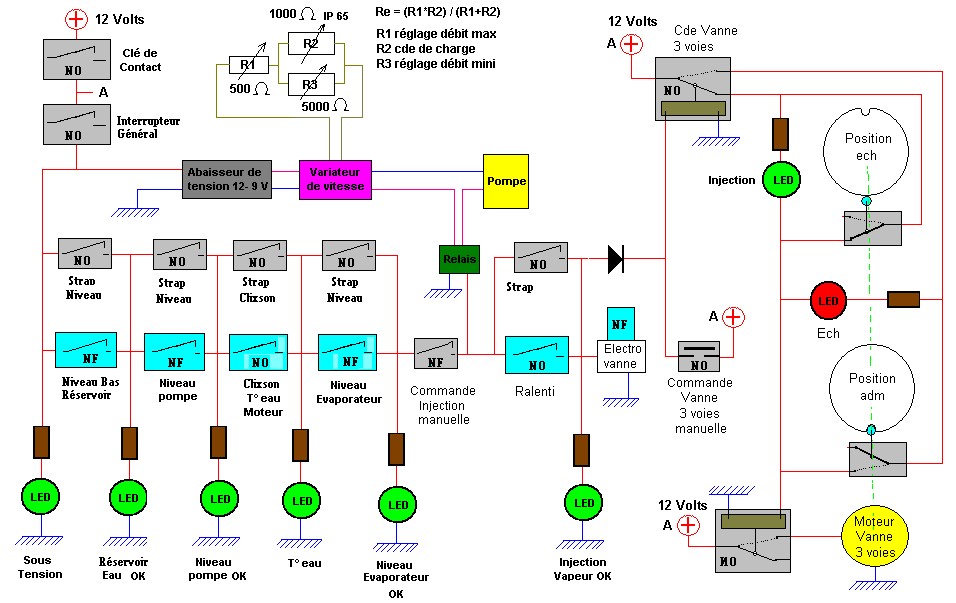

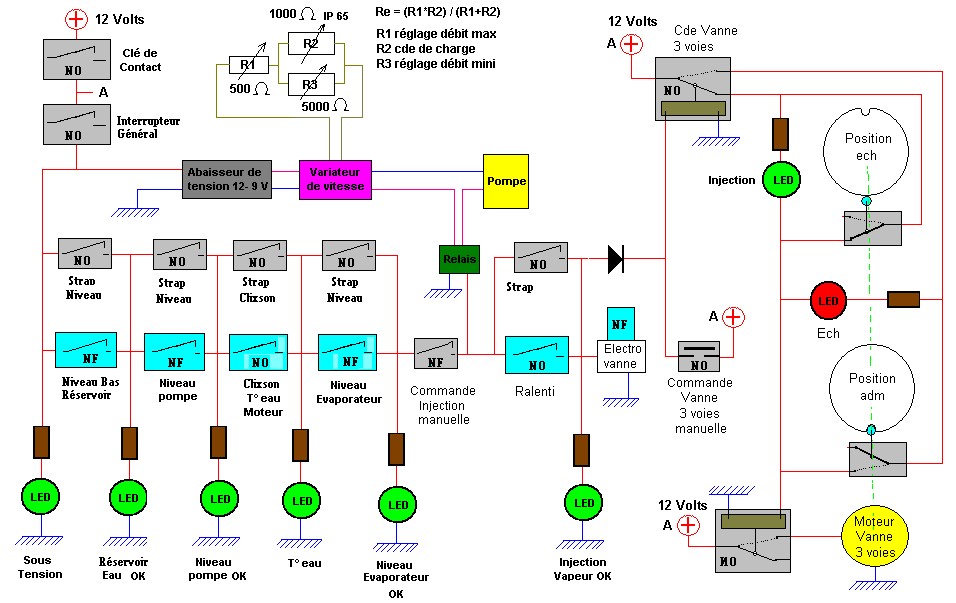

Legend: Voltage step-down, Upper part of the GV, Solenoid valve 3 channels, Inlet assembly with cyclone, Electrical diagram.

(No electrician training ...... I hope it works)

Question: Is it necessary to fear that the intake resonator will condense a lot of water and cause me problems? Is it necessary to put a purge or is the passage of air energetic enough to remove the water as it condenses?

Pitmix, your assembly with constant level and pump of wiper, it happens to him to defuse 'without reason'? Mine carries bubbles from time to time. Can the pump work horizontally?

Good mechanics

Econologically yours

Flytox