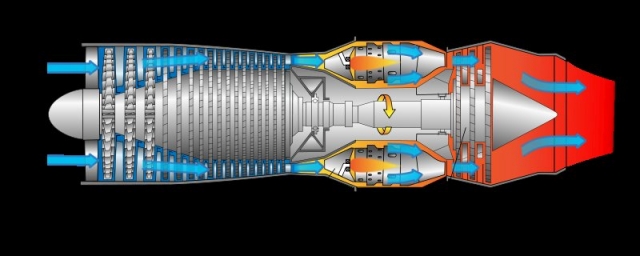

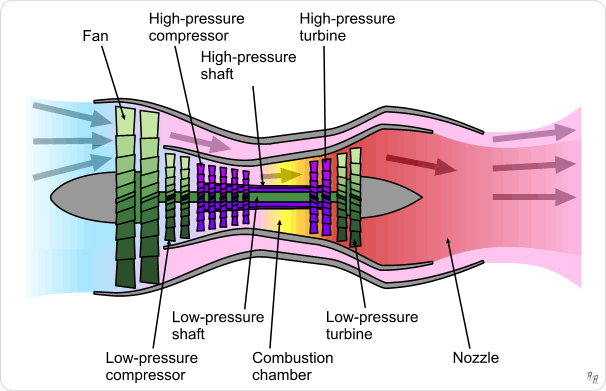

Flytox wrote:Hello Capt_MalocheCapt_Maloche wrote:for the torch effect, in aeronautics on civil aircraft reactors, the surfaces to be protected from the combustion chamber at 2600 ° C are perforated with multiple orifices into which high-pressure air is injected, in order to create a air boundary layer

there are solutions to any problem

In aeronautics too, they try to limit NOx and avoid temperatures of 2600 °. Besides, no dynamic part alloy can withstand this temperature. I think they also try to stay between 1300 to 1600 ° maximum.

No friend!

It's good 2600 ° C and compressed air at 200bar after 8 stages of compression in the combustion chamber, I was blown to learn recently from a specialist in reactor maintenance in Orly

He showed me the photos of the metal surfaces covered with ceramic and pierced with small holes for the injection of air which is used to form a protective layer

For the acidity of the water, a stainless steel pot should do the trick