by jumpy » 17/09/09, 10:34

No, not vertical, but with a slight inclination.

Each point of the blade travels a "path" = 3.14 x diameter at each turn. The further away from the axis, the greater the distance traveled. OK?

Then, the tilt angle must be calculated so that each point of the blade "advances" the same horizontal distance for 1 turn. Obviously, the wind turbine blade is not a propeller blade and therefore does not advance, but the reasoning is the same. This is to balance the contribution to the force along the blade, to distribute the mechanical forces as well as possible and above all to ensure the aerodynamic efficiency of the blade. Still fine?

The farther away from the axis, the smaller the twist angle from the vertical plane must be.

Suppose we want a pitch of 500mm; that is to say that each point of the blade will have to advance by 500 mm with each revolution.

Suppose now that the blade is screwed perfectly in the air, it is a little daring, but it allows for roughing.

First point: 10 cm from the axis of rotation. Distance covered in 1 lap = 3.14x0.1 = 0.314 m.

The angle of inclination can be represented on a triangle whose opposite side is the value of the step and the adjacent side is the value of the distance traveled. We then have blade inclination = arctangent (P / D). In our case inclination = 57.9 °.

This angle is therefore the inclination that the blade must have relative to the vertical plane at 10 cm from the axis of rotation.

We start again: second point 20 cm from the axis. P = 0.5.

D = 3.14x0.2 = 0.628 I = arctan (0.5 / 6.28) = 38.5 °

And so on until the last point 120 cm from the axis.

D=3.14x1.2=3.77 I=arctan(0.5/3.77)= 7.6°

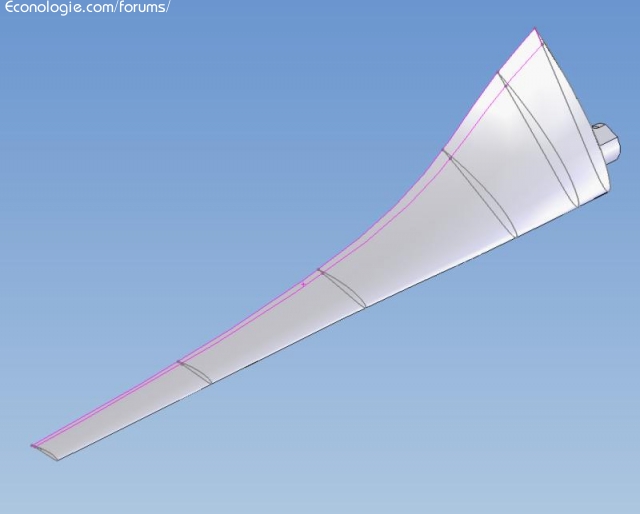

So much for the angles of inclination that the blade must have. We realize that it must be twisted ... Still with me?

To make the blade, you must first cut a thick rectangle in CTP, then cut out the projection shape of the blade (rectangular shape, more rounded shape, "lollipop", "spatula", etc ...) . I recommend the rectangular shape for the first blade.

For each point calculated previously (every 10 cms), we will measure the width of the blade, then calculate the difference in height between BA and BF that the angle of inclination imposes on us. We add to that the height necessary to cut the profile (Naca have a reference line passing through the BA while a Clark Y has a reference line which is its flat underside). And the BA + BF values are transferred directly to the blank of the blade. It is then sufficient to cut the blade while respecting these points as the reference line of the profile. The twist and the profile are then cut directly from the mass. It's long, but very stable over time. There, it is more robust and difficult to visualize for who has never cut a blade ...

0 x