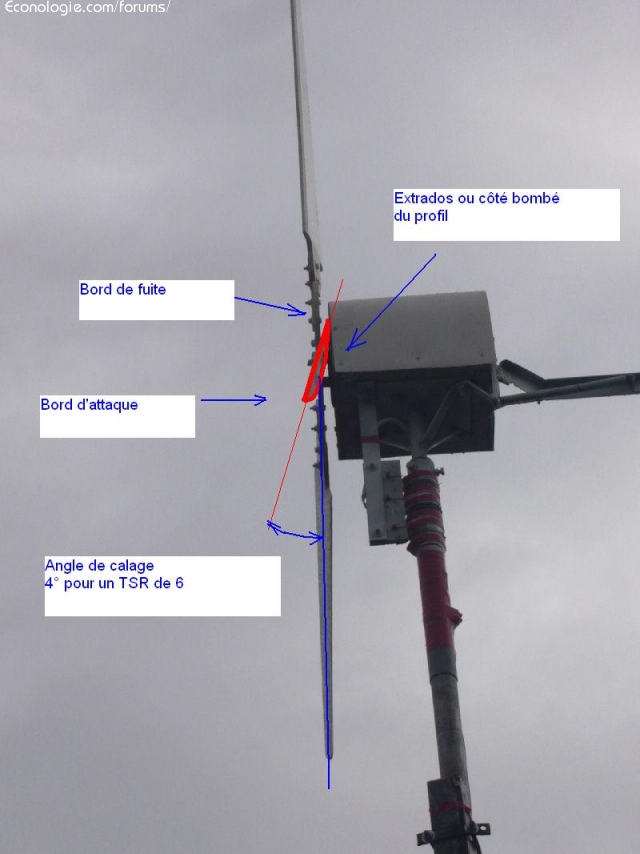

I know it is badly designed but I can't get out of it. It is made of reinforced sheet 0,5 on the back, fixed on a flat iron 3mm by 30 and on a 10mm plywood hub, diameter 30mm. Here is a photo of the shape of the blade according to photos on the net, I think the shape is correct in any case. Here are the dimensions of a blade

Length: 85cm (wingspan 1,70)

Wide width: 120mm

Blade tip width: 40mm:

The worry of dropping out in my opinion, is that the blades are too flexible, too flexible and that is what leads net, my loss of performance. I suppose that a propeller must be perfectly rigid, do not bend under any circumstances, is that it? . Can you confirm it to me ? is my wingspan insufficient? the widths?

If yes, I plan to make the same blades in 1mm sheet, on flat iron 5mm thick by 40 or 50mm wide mounted on 10mm aluminum hubs.

I came back in 3 blades, why? because after many tests I observed this.

A 5 blade, starts in a weaker wind, offers better torque but in the end with a lower rotation speed than a 3 blade and lower efficiency. I observed it by the measurements of tensions.

A 3 blade, requires a little stronger wind, offers less torque but a significantly higher speed of rotation and a much better yield going up to double on the tensions measured by identical wind. Here is my conclusion. So I opt for a three-blade after my many tests.

Thank you for your advice, I need a perfectly reliable propeller with a very good performance. My current propeller works but picks up too quickly. I know that you don't make a propeller like that, that it requires very precise rules, and that's why I take all good advice.