Hello

I wanted to have an opinion, I have a tank (25l of sncf machine in aluminum tested at 10bar)

he has no menbrane inside !!!

in your opinion (and before attacking my tests) the air inside should compress (when filling with a "made in china" pump) and function as an expansion vessel, no ??

the goal being to supply my toilets with well or rain water

ps I have a wc upstairs (approx 3m50 high) I think I would need at least 2.5 bars not? thank you for giving me your impression on this assembly (knowing that I will also put check valve and metric contact)

Problem pump booster

-

demonjoker

- I discovered econologic

- posts: 3

- Registration: 12/01/10, 19:36

- Location: mirebeau

No worries as long as there is air in the tank.

The problem is that we will have to verify that there is + - 1/4 of the

volume of air (without pressure) and renew it because

air dissolves in water (especially cold).

For the pressure 2bars will be more than enough.

3.5 meters = 0.37 bars

1 bar min to operate a Honey washing machine.

0.5 bars so that it flows well.

-----

1.5 bars are a good base.

The problem is that we will have to verify that there is + - 1/4 of the

volume of air (without pressure) and renew it because

air dissolves in water (especially cold).

For the pressure 2bars will be more than enough.

3.5 meters = 0.37 bars

1 bar min to operate a Honey washing machine.

0.5 bars so that it flows well.

-----

1.5 bars are a good base.

0 x

-

demonjoker

- I discovered econologic

- posts: 3

- Registration: 12/01/10, 19:36

- Location: mirebeau

Hello,

To be efficient, the tank must be vertical and the water inlet of the pump and the outlet to the installation must be at the bottom so that there is always compressed air at the top of the tank, on the other hand the pressure switch can be anywhere. 25l for the tank seems too little to me, you will not manage to have a sufficient air pocket for it to work because to put under pressure you need at least 25l and as you will not manage to compress these 25l in the top of the tank since there is a part that will go into the pipe, and as a flush does not deliver much the pump will start every 10 seconds (depending on the pump flow) to keep the pressure. That's just my opinion. I am talking to you as a user since I have this system with a 150l tank, vertical and installed as said above, and I put it back in the air every 6 months. When I say "put back", it suffices to completely empty the tank and once empty and therefore full of air, we close all the valves (and especially the departure one to avoid compressing the air in the pipe and once the mano has been triggered, this valve is reopened and it is off for 6 months. We notice that more air is lacking at the frequency of starting the pump.

To be efficient, the tank must be vertical and the water inlet of the pump and the outlet to the installation must be at the bottom so that there is always compressed air at the top of the tank, on the other hand the pressure switch can be anywhere. 25l for the tank seems too little to me, you will not manage to have a sufficient air pocket for it to work because to put under pressure you need at least 25l and as you will not manage to compress these 25l in the top of the tank since there is a part that will go into the pipe, and as a flush does not deliver much the pump will start every 10 seconds (depending on the pump flow) to keep the pressure. That's just my opinion. I am talking to you as a user since I have this system with a 150l tank, vertical and installed as said above, and I put it back in the air every 6 months. When I say "put back", it suffices to completely empty the tank and once empty and therefore full of air, we close all the valves (and especially the departure one to avoid compressing the air in the pipe and once the mano has been triggered, this valve is reopened and it is off for 6 months. We notice that more air is lacking at the frequency of starting the pump.

0 x

Regards

THE COIL

__________________________________

A well-defined question will have a very detailed answer

THE COIL

__________________________________

A well-defined question will have a very detailed answer

hello demonjoker

with a 25 liter balloon it does, it will just be necessary to supply air more often (every 3 or 6 months) .when the starts become more frequent.

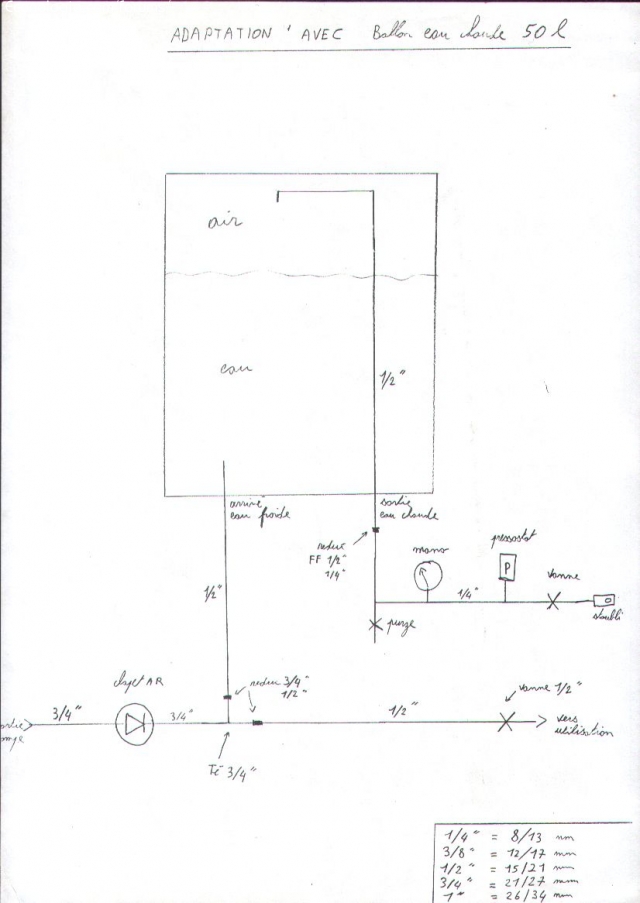

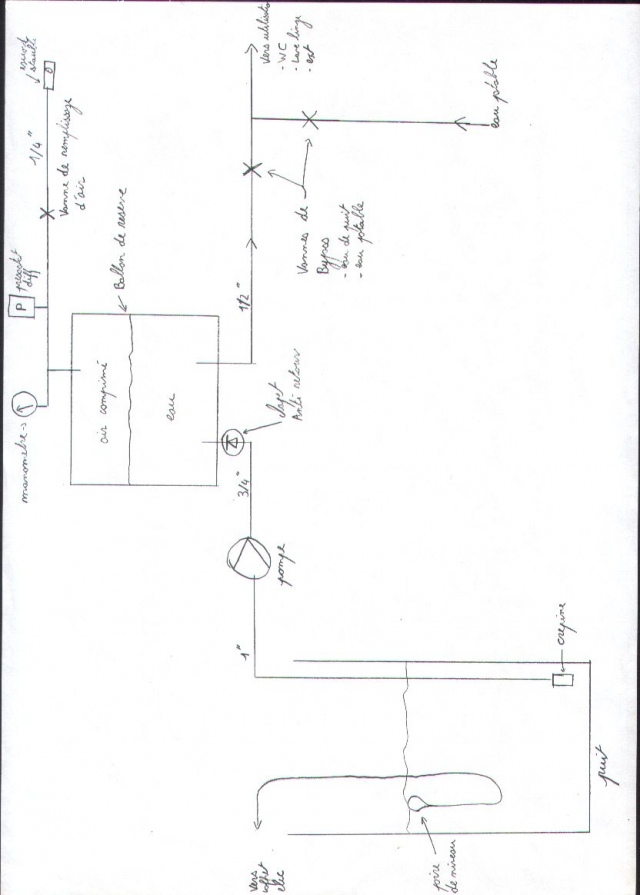

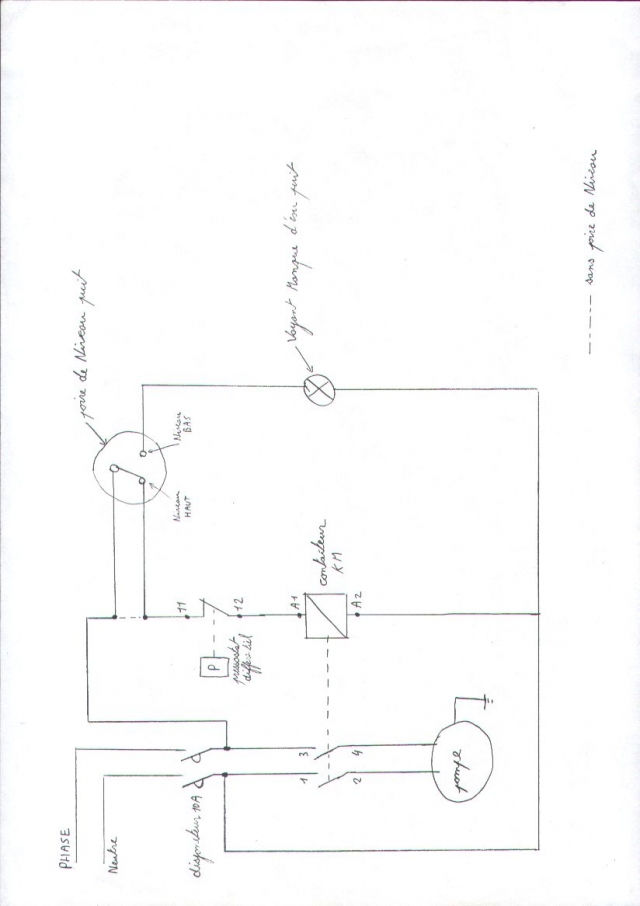

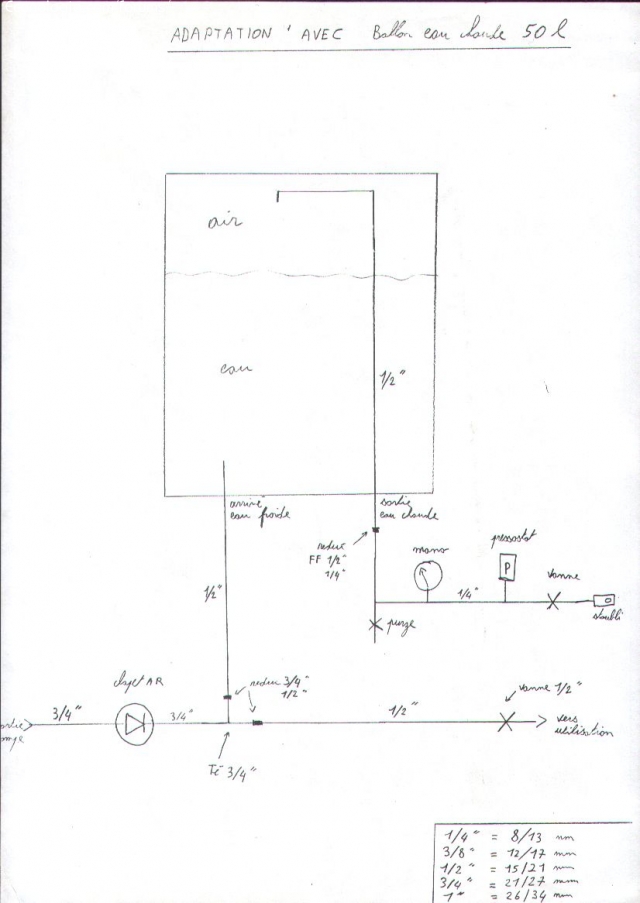

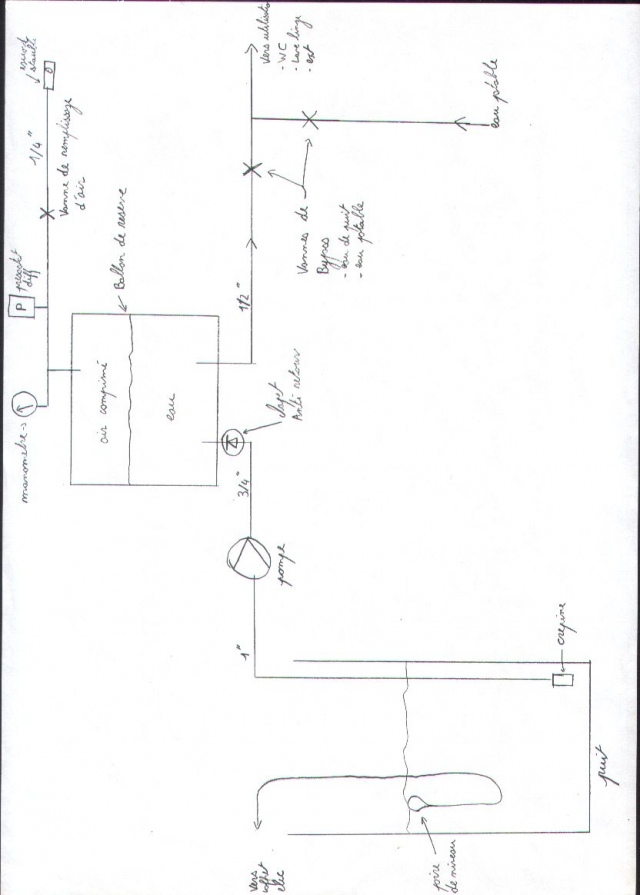

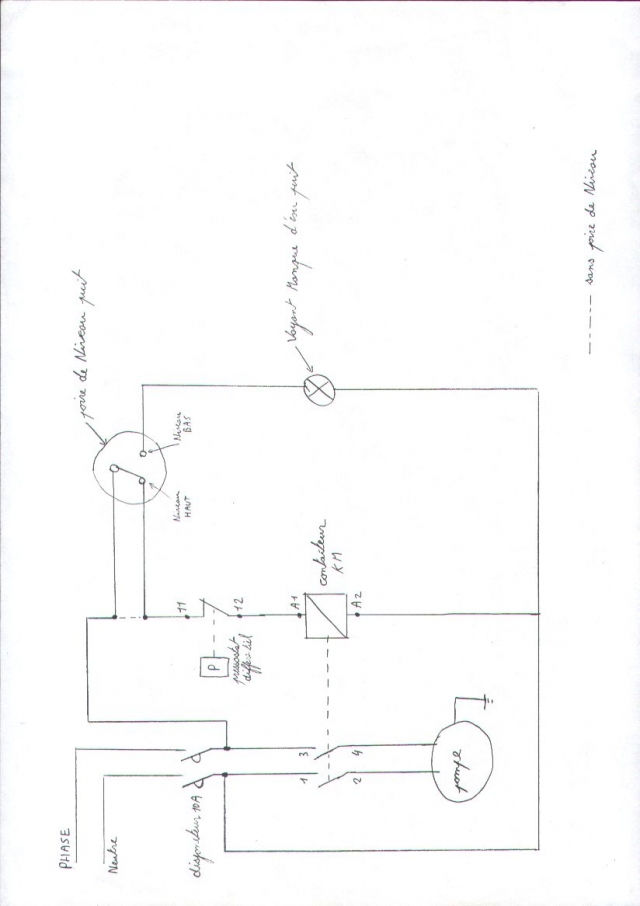

here is a sketch that I had made for a friend with the same project.

it's been 5 years and no bp.

there are just two things to modify on the sketch, it is necessary to put back the valve ar just after the strainer (in general it is equipped with it).

and put an ar on the potable water bypass for pollution control

with a 25 liter balloon it does, it will just be necessary to supply air more often (every 3 or 6 months) .when the starts become more frequent.

here is a sketch that I had made for a friend with the same project.

it's been 5 years and no bp.

there are just two things to modify on the sketch, it is necessary to put back the valve ar just after the strainer (in general it is equipped with it).

and put an ar on the potable water bypass for pollution control

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 22 Replies

- 8152 views

-

Last message by phil59

View the latest post

20/07/22, 09:49A subject posted in the forum : Failure, troubleshooting and repair: repair yourself?

-

- 6 Replies

- 9284 views

-

Last message by Doudou22

View the latest post

06/08/21, 08:38A subject posted in the forum : Failure, troubleshooting and repair: repair yourself?

-

- 4 Replies

- 16255 views

-

Last message by virfred

View the latest post

01/09/23, 11:44A subject posted in the forum : Failure, troubleshooting and repair: repair yourself?

-

- 7 Replies

- 15742 views

-

Last message by izentrop

View the latest post

22/02/20, 21:10A subject posted in the forum : Failure, troubleshooting and repair: repair yourself?

-

- 100 Replies

- 57346 views

-

Last message by EKliptus

View the latest post

19/12/23, 23:46A subject posted in the forum : Failure, troubleshooting and repair: repair yourself?

Back to "failure, troubleshooting and repair: repair yourself? "

Who is online ?

Users browsing this forum : Google Adsense [Bot] and 87 guests