manoria68 wrote:Hi, thank you for devoting yourself to this before I do something unnecessary

You're welcome, I'm unfortunately not here this week so I hope I can get you ideas by then!

manoria68 wrote:Where is the red line, it is the gas butterfly.

Okay, so this cable is connected to the cable that goes to the accelerator in the passenger compartment.

manoria68 wrote:I don't have a flow meter

Really?

How does the calculator calculate the injection? Simply by the position of the butterfly? (you see electrical connections on this butterfly?)

Are you sure there is not a valve that measures the air flow in your air filter (no electric wire connected to it)?

Or is there a capsule which measures the vacuum between the intake manifold and the outside and which deduces the amount of air which must be being swallowed by the engine according to its speed?

The U-shaped pipe to which you connected the outlet of your pantone, what was it used for? Ah yes, on your diagram you indicate that there was the idle solenoid valve, right?

The shutter that you drew on your diagram is it you who added it so that it sucks enough on the pantone, right?

manoria68 wrote:It is between the latter and the air filter that I think to put the venturi

It would surprise me that it spoils ...

The best is to place a tube whose end is biased just after your butterfly.

I think the problem in your current assembly is that the U-tube on which you plugged the output of your PMC short circuits your PMC too much since the air has easier to pass through this U than to pass through the PMC then by the end of the U.

In addition, if the assembly corresponds well to your diagram, the idle adjustment valve is located after your PMC. However as soon as your engine takes turns, I think that this valve closes since its only role is to regulate the idling. Suddenly, no more suction at all on your PMC.

If I was not mistaken in what I tell you above, here is how I would do it for you (non-destructive mounting for your air box):

1- the end of the U-tube which is connected just after the butterfly valve, you connect it with the idle control valve directly on the breather (it is the other tube which goes from the cylinder head cover to the air box).

This way it will less disturb the venturi effect when arriving in the middle of the air box.

2- by the connection thus released just behind the throttle valve, you slide a tube which fits directly there and you push it in until its end reaches the middle of the circle formed by the section of the throttle valve. Give at its end the bizarre shape necessary for the venturi effect. Check before making all this modification (including my number 1), that the tube thus pushed does not bang against the throttle when it is in full opening (yes, it would be annoying).

I hope that my explanation and my diagram are roughly understandable (not easy to do from a distance!).

Normally, the section at the throttle level is narrower than the air box behind it, so you can get a venturi effect easily without having to do a whole assembly with discounts etc. This is what I did and at home depression is top on all diets.

Your ethanol injector I imagine that you can leave it on the outlet line from PMC to air box, it will also benefit from better suction.

By the way, at the air intake of your PMC, you put a filter? Because it is still better for your engine, even if as André says PMC must destroy dust and others.

If you ever notice that there is a flow meter in the air filter box, you must connect the fresh air intake of the PMC between the air filter and the throttle valve in order to disturb the least possible the calculator.

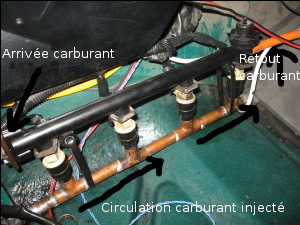

For the record, the diagram of the assembly that I made on the bus:

Good luck and see you

JC