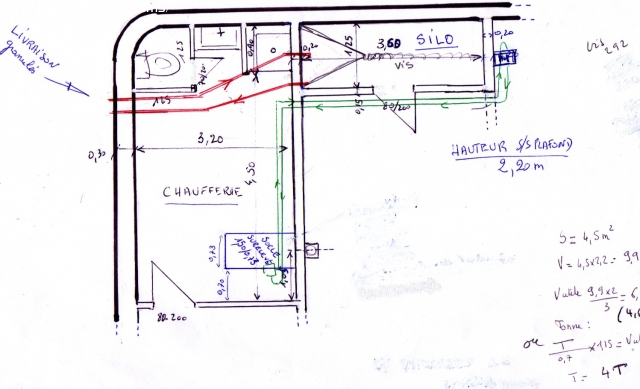

dirk pitt wrote:I am campaigning for the flat bottom silo: (that's what I have) much easier to build by favoring a long and narrow silo to minimize the "dead" volume of granules which serves as a "reserve" in the event of unexpected arrival at the end of the silo, and also of the sawdust trap because I wonder more and more if it is such a good idea to send all the sawdust in the auger with the slopes: see the blocking problems.

I am more nuanced (but not against!):

1) The shape is often imposed by the part: I built "instead" of two twin fuel tanks. So it's not always optimal to build lying down.

2) I also have a "reserve": the screw does not go all the way; as a manet, I used OSB to make an inclined plane in the bottom of the V but with about 0,5 m back from the end of the screw; I therefore have a "slice" of about 0,5 m at the bottom of the silo which does not empty (except with a shovel).

The advantage of my system (without wanting to brag) seems to me to be that once the level has dropped a lot above the screw and it's almost empty, before the new delivery, I can shovel on the screw and all this will be taken before the new pellets that I bring in ... I do not "keep" the old pellets from one year to the next ...

3) In these cases, you must force yourself to empty these pellets at least once every two / three years, otherwise they will disintegrate ...

4) Well, there remains the question of sawdust; for the moment one of the two problematic cases we are talking about elsewhere, that is not it; the second one waits; almost all of the screws work (a few thousand Okofen, to name just our common brand). So this is an assumption.