Hello,

As this engine is designed for a certain longevity I think that some parts can be reduced (width of gears and belt dist.roulements rockers ...)

The best connecting rod profile is probably classic in I as light as possible.Use the minimum amount of oil for the grease the surplus will dissipate the heat.

I will try to give another explanation that I imagine for the low engine.It must be seen as an air engine.Two discs give the law adm and ech.La difficulty is to set in motion a column of air in a conduit so that it gets into the low pressure engine like a hydraulic ram to help the piston to go up. When it comes down the extraction pipe opens, it must be in depression, I think it can be tuned with the CH.

The gain is probably not very important and amounts to recovering energy in the gas ech.

For greasing the regulation does not speak of pollution and the oil may be partly lost.

To optimize, the air intake is in a pressure zone of the body and vice versa for the extraction.

jlg

Ecoshell engine preparation

Oula, I think that using this process is not easy. To allow everyone to visualize these motor parts, I attach photos taken quickly.

* The low engine

* The vilo + connecting rod + piston + wheel ignition

* The distribution cam

Regarding the muffler, the regulation states that no recycling of gas is accepted ...

* The low engine

* The vilo + connecting rod + piston + wheel ignition

* The distribution cam

Regarding the muffler, the regulation states that no recycling of gas is accepted ...

0 x

Hello,

Do you have a photo of the cylinder head with the rockers and can we get an idea of the transmission?

The process I have described does not recycle the ech gas at all. but uses the phenomenon of the waves as in a pot of détente. On this idea I would have liked to have an opinion of people more competent than me.

jlg

Do you have a photo of the cylinder head with the rockers and can we get an idea of the transmission?

The process I have described does not recycle the ech gas at all. but uses the phenomenon of the waves as in a pot of détente. On this idea I would have liked to have an opinion of people more competent than me.

jlg

0 x

Regarding the transmission, it uses an adjustable pocket bike clutch and its bell system on which we change the bearing by a high performance. I can not give you an image of this montage for now because it is not me who follows load of its construction.

Here is an image of the bell:

This is certainly not the ideal solution but the little time we have been given to the design and construction of the prototype does not allow us to achieve too much for this first year. Moreover, no radial load on the crankshaft is allowed by Honda.

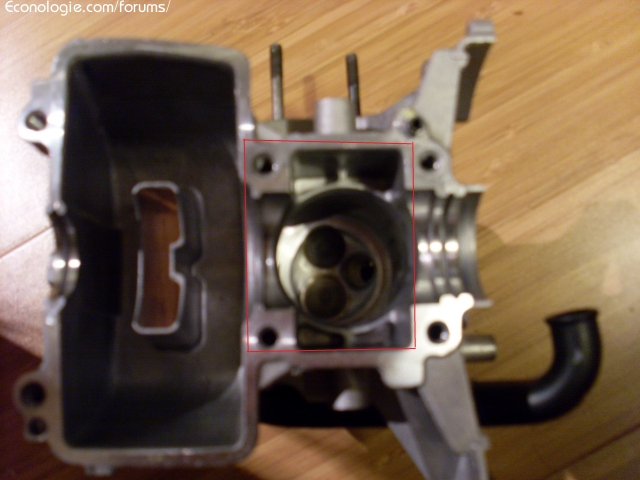

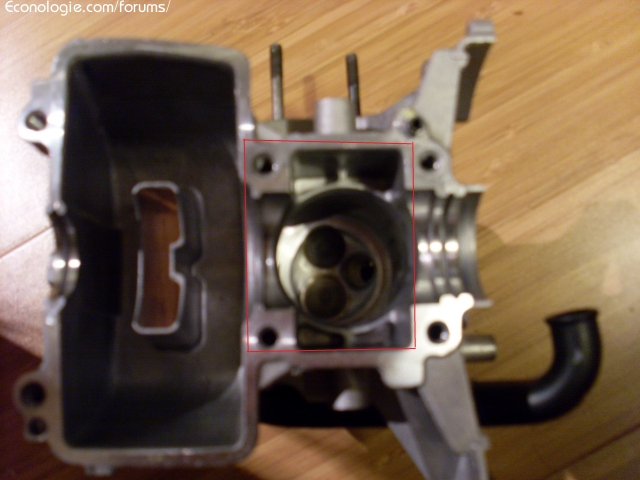

As a picture of the cylinder, I can only give you this, the high engine being 3D scaning at Mecasolution in Wavres.

Here is an image of the bell:

This is certainly not the ideal solution but the little time we have been given to the design and construction of the prototype does not allow us to achieve too much for this first year. Moreover, no radial load on the crankshaft is allowed by Honda.

As a picture of the cylinder, I can only give you this, the high engine being 3D scaning at Mecasolution in Wavres.

0 x

For the low engine, if it is splash lubrication, the oil level can be optimized (decreased) to avoid losing a handful of Watts. The aerodynamics / hydrodynamics of the crankshaft counterweight greatly contribute to this loss of power when it functions as a cylinder at the bottom of the crankcase.

For the reserve of compressed air in the plastic bottle is a good system .... if the regulator works with very little hysteresis otherwise we do not know what is injected.

For the friction of the piston, it is possible to define zones on the skirt out of the guiding zone, the thickness of which can be reduced by approximately 2 / 10mm by sanding with a mask. These areas do not rub directly but are filled with oil in operation and still allow the evacuation of calories. The piston is practically not weakened and this does not require a new balancing.

For the reserve of compressed air in the plastic bottle is a good system .... if the regulator works with very little hysteresis otherwise we do not know what is injected.

For the friction of the piston, it is possible to define zones on the skirt out of the guiding zone, the thickness of which can be reduced by approximately 2 / 10mm by sanding with a mask. These areas do not rub directly but are filled with oil in operation and still allow the evacuation of calories. The piston is practically not weakened and this does not require a new balancing.

0 x

Reason is the madness of the strongest. The reason for the less strong it is madness.

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

It's an interesting idea.ggdorm wrote:Thank you very much for this idea Flytox, it is indeed quite judicious!

I do not know much about tribology. It should therefore be ensured that the lubricating film will not degrade the coefficient of friction.

Regarding the low engine, I think on the contrary that there is material to optimize:

- Crankshaft polishing

- Possibly, lightening and balancing the crankshaft

- Reduction of the oil level to reduce the bubbling, or lubricate by dry sump ...

I personally think that consumption measures should also integrate the electrical consumption of thermal vehicles.

This was also a cause of fraud for many years, some competitors using electric starters to propel their vehicles in place of thermal engines ...

For dry sump lubrication, it is therefore possible to imagine pressurized oil spraying lubrication via an electric pump actuated during the operating phases of the engine.

0 x

I think I read a clause prohibiting the use of electricity for the operation of the engine other than the starter and the injection box unless the electrical energy is provided by the engine ... Which would cause concern for lubrication by pump. It would be necessary to see if the gain obtained by an external oil tank and a mechanical pump would be greater than the loss due to the friction of the elements turning in the crankcase oil but by intuition I do not think. Maybe I'm wrong.

Concerning the starter, a visible red light must come on when it is put into operation and during the technical control, it is asked to start it ignition engine off to verify that it does not drive the vehicle.

Concerning the starter, a visible red light must come on when it is put into operation and during the technical control, it is asked to start it ignition engine off to verify that it does not drive the vehicle.

0 x

citro wrote:For dry sump lubrication, it is therefore possible to imagine pressurized oil spraying lubrication via an electric pump actuated during the operating phases of the engine.

Or if regulation allows, use the pressure pulses of the exhaust to pump the same oil with a small diaphragm pump.

0 x

Reason is the madness of the strongest. The reason for the less strong it is madness.

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

[Eugène Ionesco]

http://www.editions-harmattan.fr/index. ... te&no=4132

I will review all this tomorrow especially in the new regulation in English to see if things have changed regarding gas recovery!

Otherwise, a pressurization hold in the pot to push the oil with a needle to limit the amount that passes to the image of the fuel supply of an RC airplane ...

How will the oil recovery be done? Via a simple pipe in the low engine and a pressure / gravity evacuation with a tank placed under it?

Otherwise, a pressurization hold in the pot to push the oil with a needle to limit the amount that passes to the image of the fuel supply of an RC airplane ...

How will the oil recovery be done? Via a simple pipe in the low engine and a pressure / gravity evacuation with a tank placed under it?

0 x

Back to "Special motors, patents, fuel consumption reduction"

Who is online ?

Users browsing this forum : No registered users and 124 guests