PlasmHyRad project, Hydrogen and Radical assisted combustion.

by JM Cornier, University of Orléans, GREMI - CNRS - MINISTRY OF RESEARCH.

Electric plasma ionization project of combustion air and fuel to improve the efficiency and pollution control of internal combustion heat engines. The tests relate to methane, the simplest of the hydrocarbons.

This document was useful to us during the research phase on water doping in connection with ionization of water vapor which would greatly favor combustion.

Summary and summary presentation of the results.

The first tests were carried out at GREMI with a tubular laboratory reactor comprising two parallel electrodes. The power supply used is a voltage-lift magnetic leakage transformer (220V / 15kV) at 50 Hz.

The first objective was to define methane air mixtures that could be used, knowing that the concentration limit of methane is defined by the HEL which is 15% and that carbon deposition is prohibited in order to allow the operation of the engine. The tests were carried out at atmospheric pressure.

Analysis of the gases leaving the reactor has shown that significant hydrogen production is observed as well as carbon monoxide. The concentrations of hydrogen, carbon monoxide, carbon dioxide, oxygen and nitrogen were measured by gas chromatography.

These first results confirmed the validity of the idea generating the project: it is possible to enrich with hydrogen a gaseous mixture containing methane and air.

In this first study the concentrations of CO2, H2O and other hydrocarbons were not measured because the experimental setup was not complete.

However, this first study made it possible to define the range of usable methane concentrations. It has thus been shown that it is possible to work with mixtures containing a minimum of 16% methane in air and a maximum of 30% if it is desired to avoid any carbon deposition.

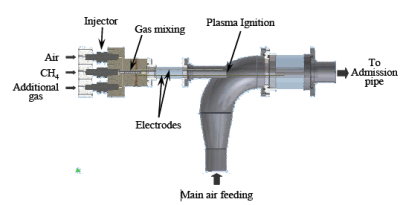

We have developed an inverter power supply that synchronizes the plasma priming and expansion phases with the opening of the inlet valve. From the results obtained we have built in collaboration with the LME a prototype reactor according to plans made by Christophe MET.