Page 1 on 3

Printer 3D K8200: Installation, configuration, calibration ...

published: 25/07/13, 11:00

by Christophe

The 3D printer from the store is available at the presale for delivery in October 2013: https://www.econologie.com/shop/impriman ... p-511.html plus a launch promo (and always Franco de Port)

There is about 15 to 20h mounting.

I open this topic for user feedback on the hardware and configuration of the K8200.

For the use and exchange of 3D models other topics will follow here:

https://www.econologie.com/forums/imprimante ... -vf95.html

published: 12/08/13, 23:44

by genesis2546

hello, good idea!

At the moment I am on 115 page on 764 ...

the manual is very good!

following your skills in DIY, 1 day for editing + commissioning is a little optimistic ...

I'll do a little summary when it works!

published: 13/08/13, 10:09

by Christophe

Super genesis2546, welcome and thank you for this return!

1 day is what the representative Velleman told me ... if the record does 700 pages actually ... but there are a lot of pictures !! each step is detailed, so to make a mistake you have to want it ...

ps: we have our own web host:

https://www.econologie.com/forums/comment-me ... t1176.html

published: 14/08/13, 18:59

by Remundo

I'm interested

published: 14/08/13, 20:55

by genesis2546

following events ...

I am on the 392 page on 764.

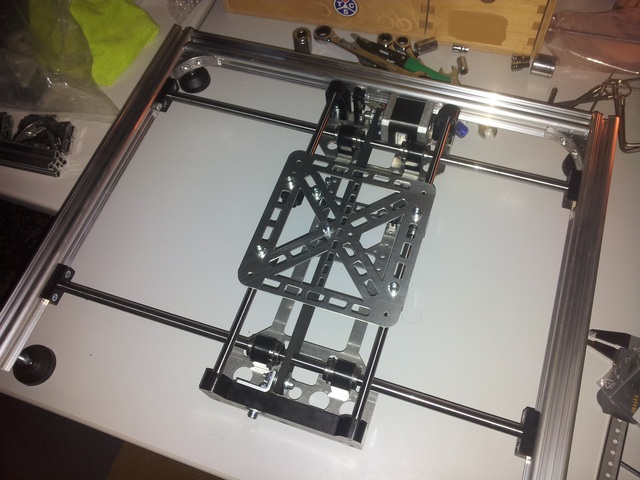

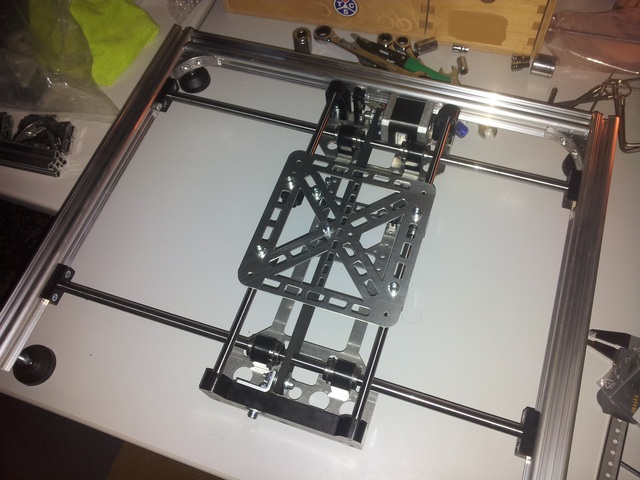

so the mechanical part is over!

Re: 3D K8200 Printer: assembly, configuration, calibration.

published: 15/08/13, 13:04

by moinsdewatt

And besides making a set of plastic cupcakes for beautiful mom, what are you going to do with it?

published: 15/08/13, 14:27

by Remundo

For Lessdewatt,

it's a bit squeaky as a remark, right?

We can do all kinds of objects: figurines, prototype parts, keychains, dimensional validation, small mechanisms ...

obviously, we do not run a Diesel cylinder head with that.

published: 16/08/13, 23:24

by genesis2546

After...

So the printer is working properly globally!

But the heated "bed" is not very flat, not easy to adjust (fold) ...

the Z axis moving with the filtée rod, not top to improve (the motor slime a max).

Little trick for commissioning the electronic card:

Connect it to the PC with the usb cable, but without the power supply 15V and no plug ... once the PC communicates (com port), you can connect everything ...

Otherwise really top !! it's really cool to see it work.

the "repetier" program is very easy to use!

if you have any questions, I'm here ...

published: 18/08/13, 21:25

by genesis2546

Hello,

good the heated "bed" was rounded! So to be able to adjust the bed as well as possible, a 5th screw has been added (in the center)!

For 3D modeling I use Inventor 2012, which export directly to .stl format.

For printing,

Repetier-Host (in French) works perfectly! the Slic3r "slicing" program (in English) allows many adjustments ... I still have to go deeper ...

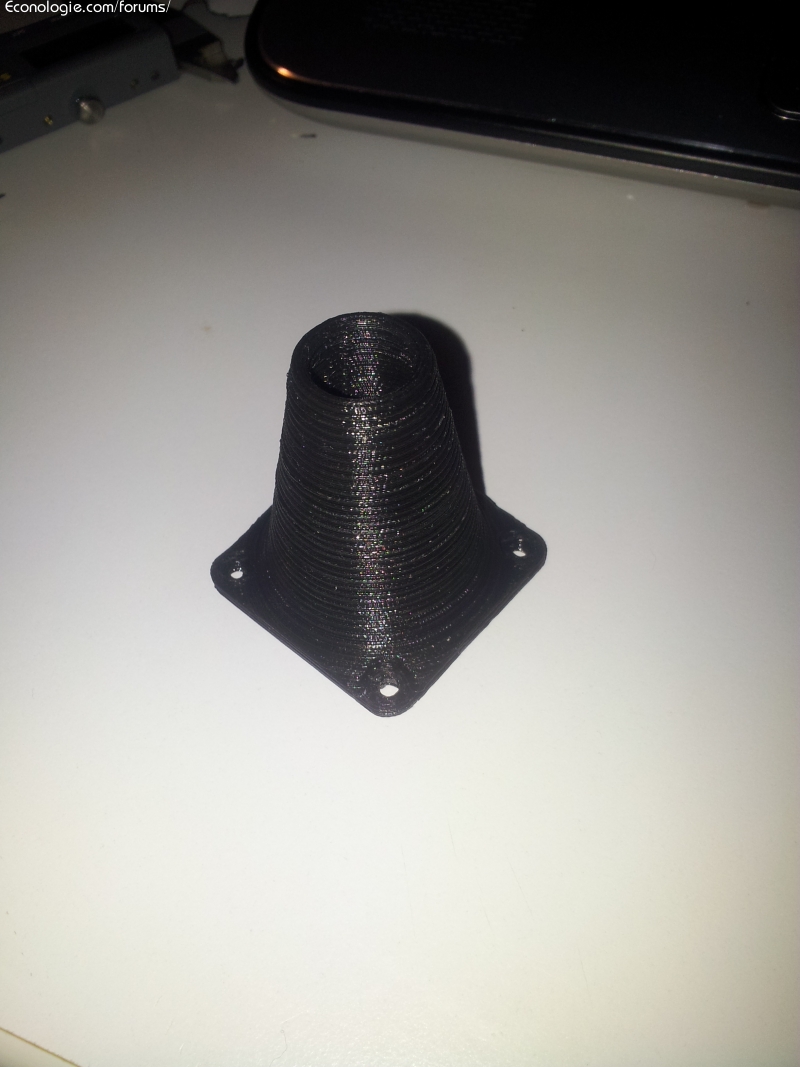

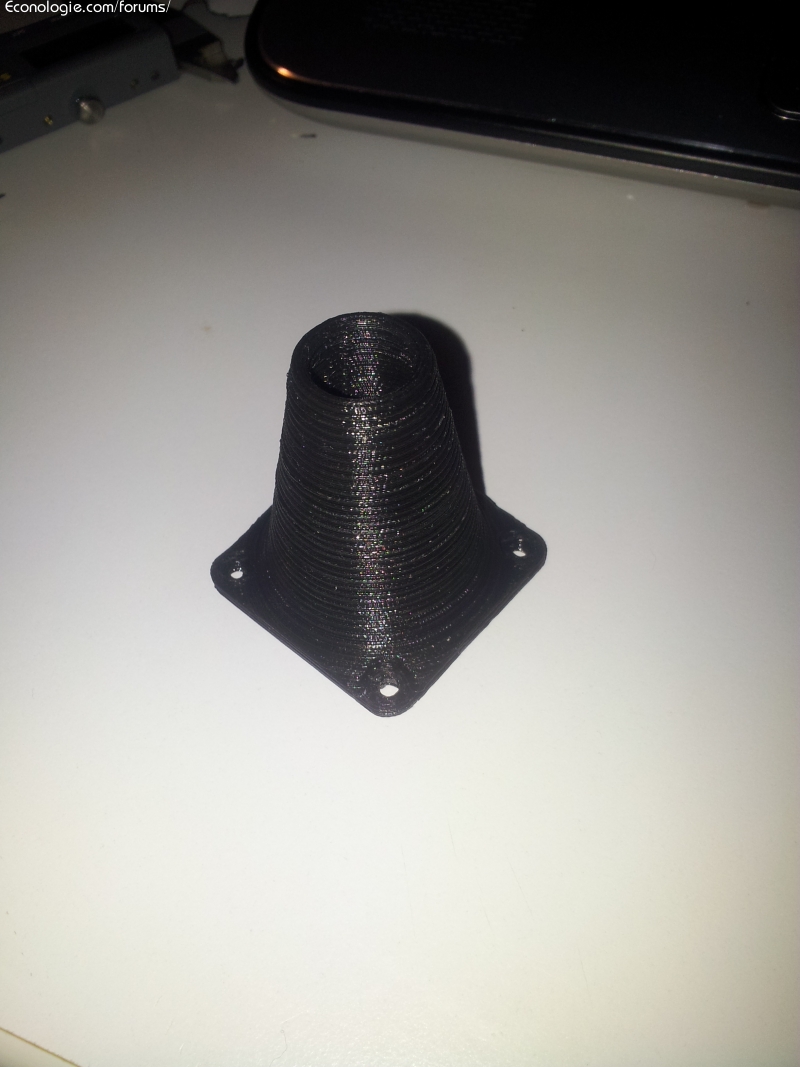

one of the first piece to print is the cone for the fan ...

this is the result:

In the end it's still nice to be a handyman to mount this printer ...

published: 18/08/13, 23:08

by SixK

In the picture, the finish of the piece does not seem top, is the photo that is misleading?

comments do you think you get a correct finish, Dremel, sandpaper, lime?

SixK