So my experiments concluded with two results: No water consumption by the engine (or consumption not verifiable), secondo the machine works with vaporized gasoline until the most inflammable components of this gasoline is burned ; leaving me with about a quarter of useless unused petrol ...

Thus the system put in place only vaporizes and heats gasoline but does not consume water. A reduction in smoke is still a great advantage (especially when the engine is running in a garage.

The water consumption could surely be improved if the temperature of the bubbler could be increased, but considering the size of the machine, even after modification of the place of the bubbler just at the outlet of the exhaust, the temperature is not sufficient for spraying water.

Your advice and comments are welcome for this first experiment.

Even if now I want to tackle a small tractor.

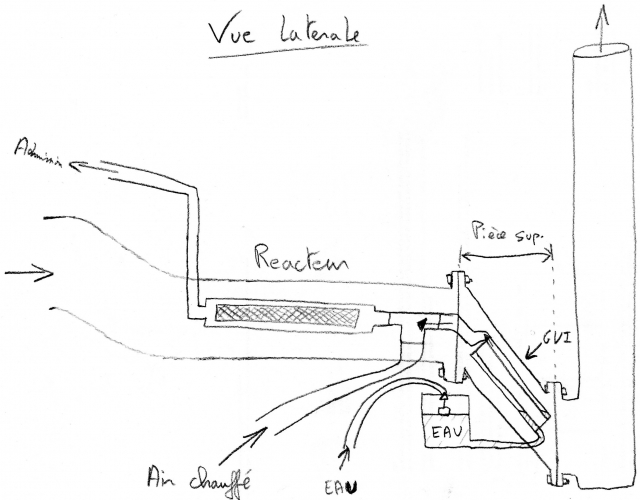

The photos and plans will follow, I plan to put together a file with all this to present it to those who are responsible for this tractor and thus convince them of the possibility of doing so. So with your help everyone I would like to put a system with GVI on this tractor.

The exhaust outlet is divided into three at the engine outlet. I plan to put the reactor in the central branch. A tube for heating the air in a right branch and connected to a T at the inlet of the reactor and to an auxiliary air filter. Then there is room to insert the GVI just before the T at the inlet of the reactor.

I think it's a 1.2 liter displacement, I'm not sure but it will also follow. My questions will also follow.

I will publish scale plans later together with the photos.

In the meantime, your comments and encouragement are welcome!