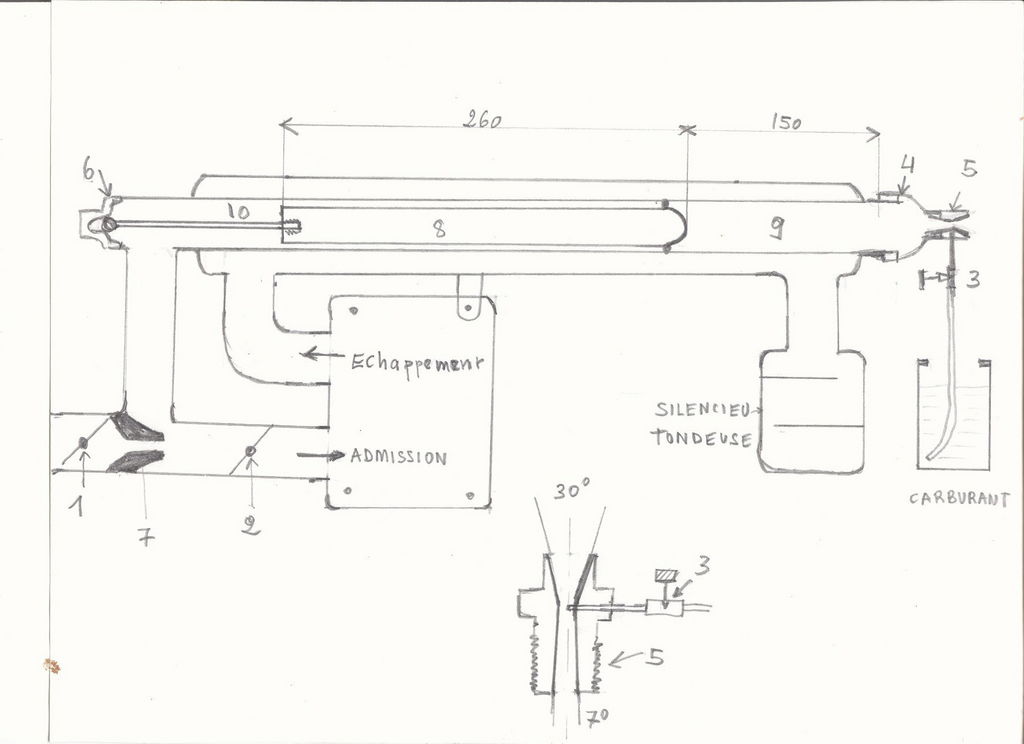

Small panton assembly that works multi-fuel.

1 air intake control valve

2 engine power control valve

3 needle valve carburetor richness control

4 reduces 1 / 2 to 1 / 4 pipe

5 Carburetor

6 1 / 2 pipe cap

7 venturi for suction in the reactor

8 reactor rod 12, 7mm

9 anteroom

10 relaxation room in the hottest part

The rod is made of 12 steel, 7mm in diameter 260mm length

The play in the reactor approximately 1mm

it has 3 welding points at the entry which is rounded, the exit is cut square without centering point it has a rod of 3 mm screwed in the center and which ends with an eyelet supported in the cap, this allows its extraction easily and that keeps her positioned.

The tube reactor of 1 / 2 threaded pipe at the ends

the 1 inch pipe exhaust pipe casing to be welded to the reactor, two 1 / 2 pipe fittings are welded for exhaust inlet and silent outlet.

All elements are screwed with elbows and T plumbing

All conduits are in 1 / 2 pipe targeted

1 and 2 valves are ball valves

the 7 venturi is used to increase the depression in the reactor

The body of the reactor shell is screwed onto the cylinder head and must be thermally insulated.

The silencer comes from a mower it is screwed on the body of the reactor 1 / 2 pipe

The 4 cast iron reducer and to receive the carburetor

The fuel is sucked in at a height of 200 mm and the flow is controlled by a small needle valve

The carburetor is a simple brass fitting of 1 / 4 pipe, we drill a hole with a wick sharpened at 30 degrees and the outlet with a wick sharpened at 7 degrees, the reduced passage makes 4 mm, in this reduced we weld a small tube of 3,2mm with a Bic tip from which the ball has been eliminated, the carburetor is ready

Start-up

we start with petrol

we open the needle valve slightly

we close the 1 valve completely, we open the 2 valve to 100%

we start the engine, once running at the start it is rich

once warmed up, the 1 valve is quietly opened and the richness is reduced by the 3 needle valve

Once the reactor is hot, to increase the power

enriched by the needle screw then slowly open the 1 valve to work at the right ratio.

this operation can be done gradually until the full power of the engine.

At this stage you can control the power only by the 2 valve.

Once the engine is hot you can interchange the fuel pot with fuel oil or alcohol, without stopping the engine just changing the flexible jar duct. and readjust the richness, to the mazot little difference, to the alcohol it is necessary to enrich especially if it diluted with water.

when the reactor is operating well you can touch the muffler with your bare hands.

You can also walk with water and alcohol mixtures

We can on the inlet of the 5 carburetor suck water vapor in small quantity, either from a fogger or a bubbler heated with the exhaust or another water inlet opposite that of gasoline in the same small carburetor the water must be heated, it tends to cool the reactor (although the water in this small engine does not bring much efficiency in the same reactor a slight depletion when I enter the vapor in weak quantity in front of the carburetor)

This small motor starts with an electric motor of 0,5 CV once running this motor becomes generator the load it is two lamps of 100watt. The tests are done by measuring with the same load the time to consume a jar of 0, 5 liter of different fuel, all tests were done by comparison.

Andre