Gaston wrote:Asynchronous motors are not necessarily well suited to traction.

Their efficiency is (a little) lower, their driving is much more complex and their starting current is very important (or if we limit the starting current, the torque is lower).

In fact, it's the most suitable type of engine (with the SRM starting to arrive), which is why we can not find more than that in recent trains, trams, subways, boats, etc.

The steering is complex but it is not a problem for modern electronics. For the SRM, the steering is even more complex, but the engine is smaller, cheaper and more efficient, which largely offsets. The complexity is mostly code ... which costs nothing in production costs, only in development. If you replace a kilo of copper with code, you make money. A more powerful DSP to drive the engine costs less than copper 500gr ...

So, for traction, what is interesting is the efficiency, power and torque of the engine over the entire range of useful speeds, and over a wide range of load. And the ratio of all this to price and weight.

This is very different from an application like a pump where the motor will always run with a speed and a load almost constant.

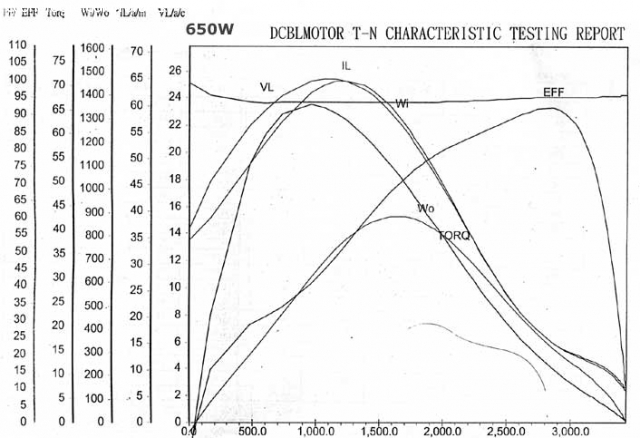

So, the brushless has an excellent performance on a small range of speeds, outside this range, it is to shit (really). But the couple is good. Extraction of rare earths (neodymium) generates an apocalyptic pollution, in addition it is expensive.

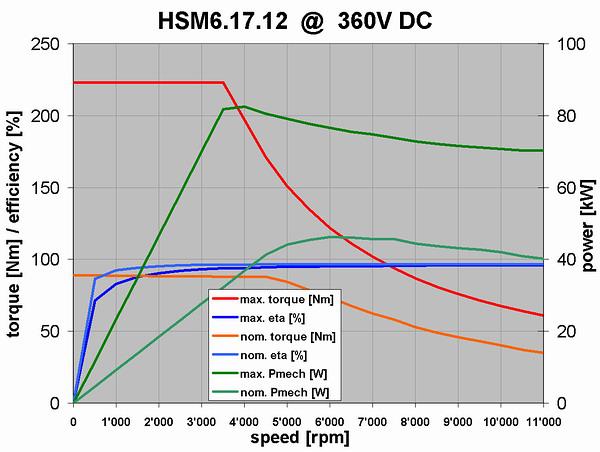

The asynchronous has a maximum yield a little worse, but it remains good over a wide range of speeds, is cheap, but is heavier and has less torque. Raising the frequency requires more gears output, but the engine becomes more efficient.

The SRM is a bit like asynchronous, better: the rotor is a piece of scrap that costs nothing, it is lighter, more output and more torque over a wider range of speeds, etc. But it's new, it's going to be democratized.

The worst of all is of course the direct wheel motor without gearbox.

> asynchronous motors are much heavier than universal motors!

The universal motor (ie, series without magnet):

- very good power / weight ratio (for the portable power is essential)

- very cheap

- very good starting torque (useful for a drill)

- yield more than le (50-60% under optimum conditions)

- short life

- fast overheating (when you have a 0.8kW motor in your drill and it has 60% of losses, it is a lot of watts to evacuate, so must blow on very strong ...)

Otherwise + 1 chatelot.

[/ Url]

[/ Url]