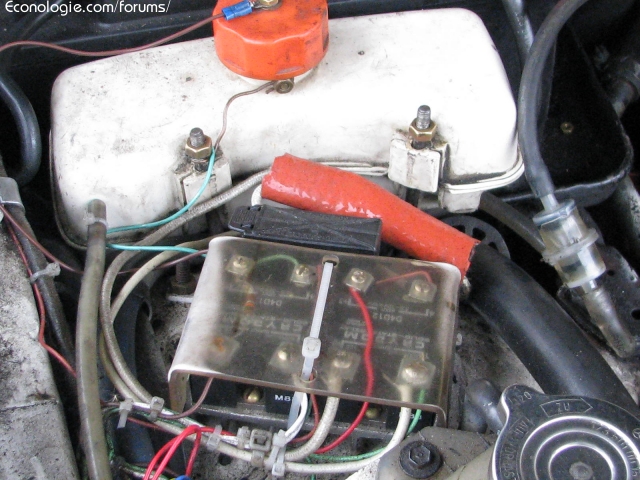

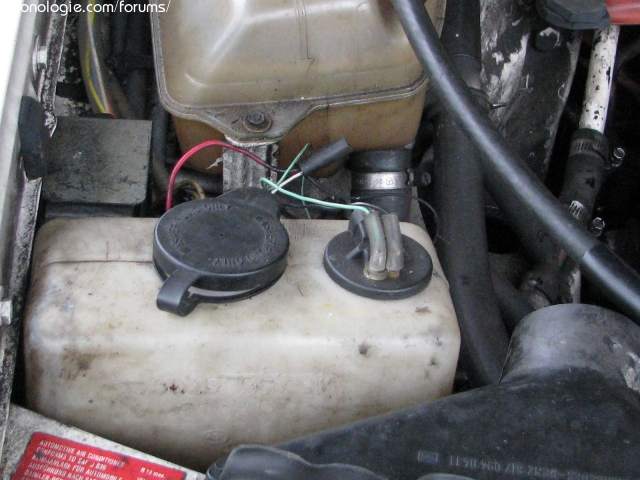

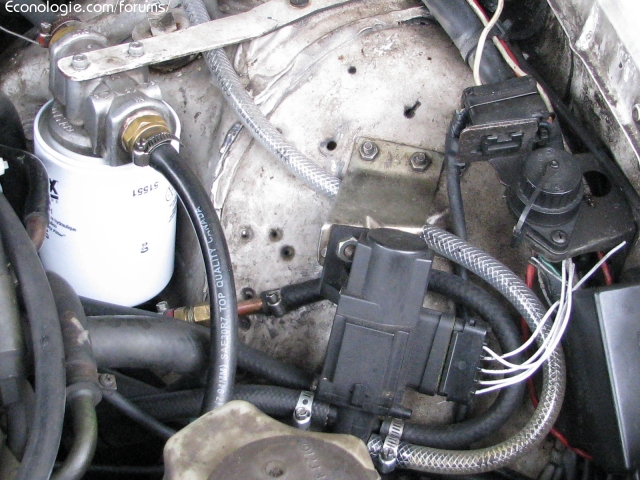

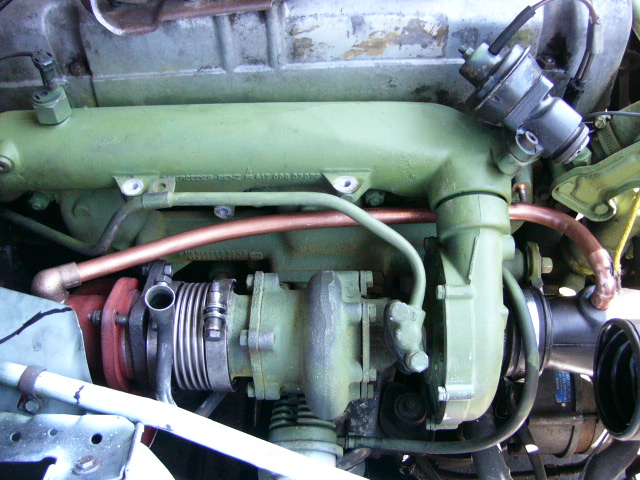

Mercedes serie 123 300D turbo diesel engine 5 cylinders 3litres 1984 automatic transmission of very rustic mechanics rather heavy indirect injection often works to frying oil suf when I make trips 280 test has 300km to have the measurement precision.

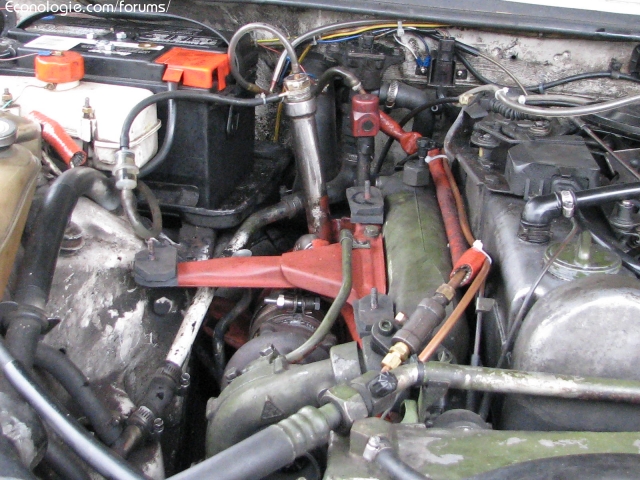

Following a problem of demister, I file the exhaust pipe which also cracked and corroded under the insulation, I deposited the system to rebuild it and examine the rod poses rune another stainless steel rod of a differrent alloy

The long rod 150mm I made 12268 km with then I replace it with a shorter 100mm with the short I made 84097 km and consumed on average 1, 2 liter of water at 100km

the vehicle currently has 414015 km.

Its best consumption was 5,9 liters at 100 when driving at 100kmh, 105 kmh, although it is often found in 6,2 at 6,7 liters at 100km.

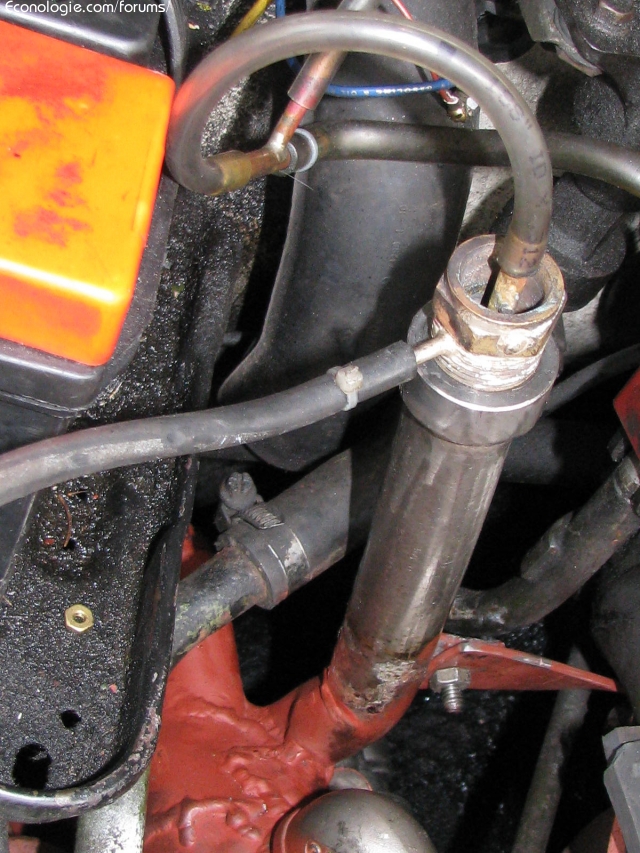

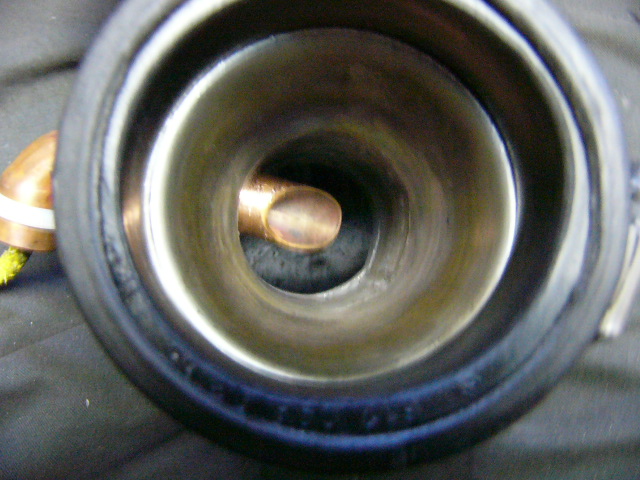

For the stem, it has a matte finish and if we look at the magnifying glass it all tingled with tiny dotted black dotted lengthwise, there is also a long helical on the short while on the long which has to walk only 12 268 km the trace of the helicopter is rather regular and with a step which corresponds to the radius of the rod this propeller is more apparrente at the output reacteur hot part.

These rods when I put them on it smooth and shiny polished finish.

When we talk about break-in it's more when the stem has a blasted appearance, the body of the reactor remains smooth but not bright rather matt at the stem, but before and beyond the stem a thin layer of limestone.

After many tries it is not favorable to overheat the air at the entrance of the reactor just around 25 35C, it gives good results must try to maintain the haze.

I can not explain why the rod is subjected to this abrasion and stitching, this rod is not insulated a central axis is welded directly to the body of the reactor to prevent vibration and wear in the reactor.

When I worked at the steelworks I brought a rod to the metallurgical laboratory and I had few explanations, he simply called it pickink but without knowing the origin of this abrassion

Some pictures