hello andré

Andre wrote:It starts to look like my montage

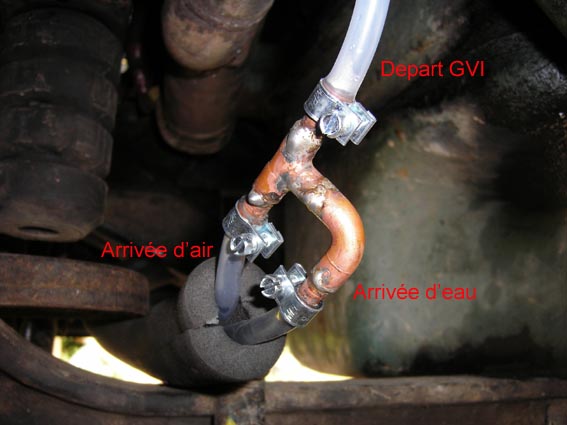

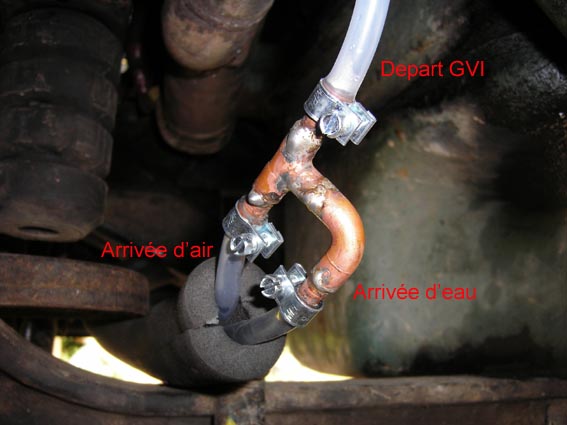

easier to manage air and water at the inlet of a dry GV while strongly welded stainless steel.

Exactly, I thought of you during the repairs, I wanted to try a simpler solution, on a forum enthusiasts of Mercedes utility vehicles, I had also been made the remark, (send the air directly in the gvi) maybe the idea comes from here

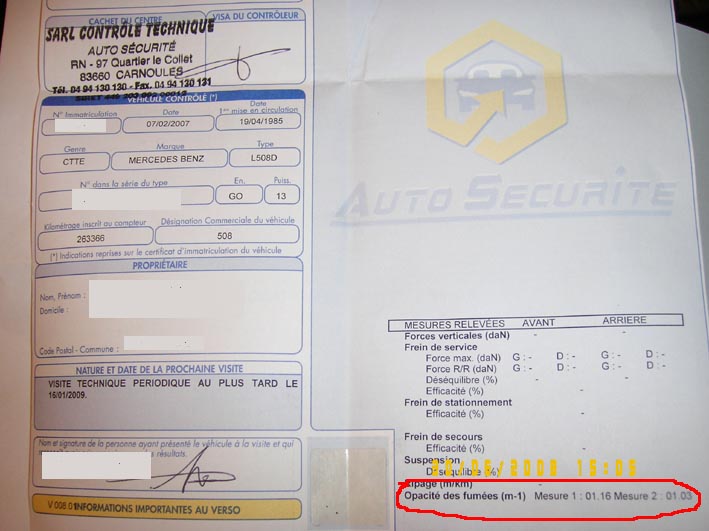

170c output with 2 liters of water, the motor must force

1,8 liters at 110kmh on the highway I stand around 110c and less .. With 1,2 liters of water it varies from 135c to 150c

The outlet temperature reacts with a lot of inertia, but once hot, you can do without water .. the economy is not proportional to the consumption of water, exceed a certain consumption of water even with hot exit you don't make any more gains ..

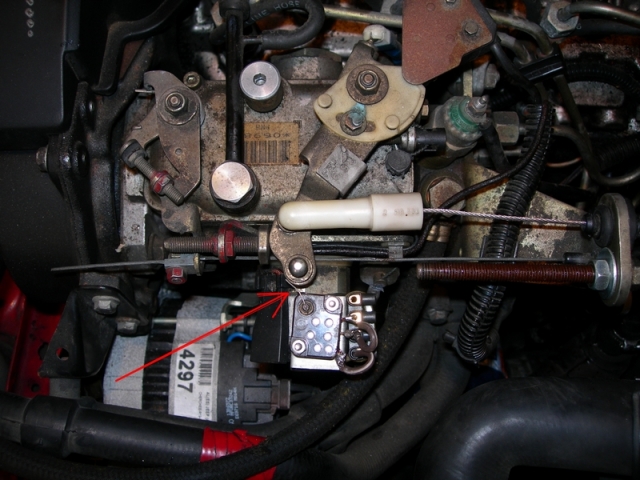

When this was lacking, did you not notice a loss of acceleration power?

Andre

to have 170 ° c, I drive in 5th at 85km / h (my maximum speed is 90km / h)

actually i wanted to test the limit of the system

I will now devote myself to finding the ideal flow rate between 10 and 20% of my go consumption, I think it will be between 0,8 and 1,5L of water per hour

When my system failed, it was especially on the climb that I noticed the change, less power and especially a lot more black smoke at the exhaust outlet

I also noticed that my water consumption was limited to 0,7L / hour, impossible to consume more when the drip was opened wide, I first assumed that the hose was blocked or pinched, but no, in fact it was the exhaust gases that were pushing the other way, it was my headache of the summer !!

Another thing that I noticed, it can be interesting or dangerous, the air-water connection serves as a buffer space to receive the water when the engine is idling (red light, stop), instead of filling the gvi, the extra water passes into the air intake to accumulate until the next acceleration.

When I restart I therefore walk without air for a few minutes, the time that the overflow of water passes through the gvi to be brought to a boil. I guess it's interesting to have a surplus of water during acceleration, this is the time when we heat the reactor the most (with the climbs)

Provided of course, that the reactor has not cooled down too much during shutdown.

Which makes me say, that it can work for small stops, in case of prolonged stop, I will have to activate the solenoid valve as usual at the risk if not to send too much water at the next acceleration, to drown the reactor and above all to send water into the engine