Hello

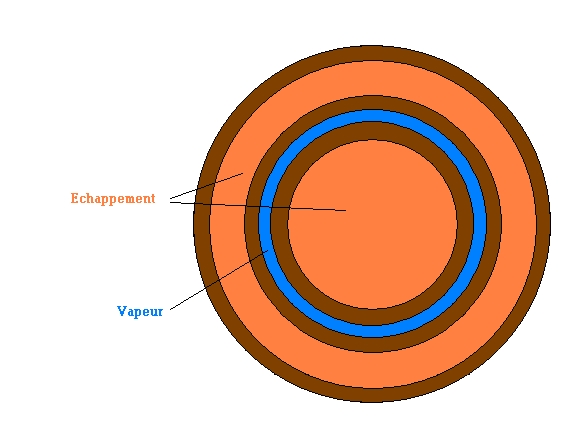

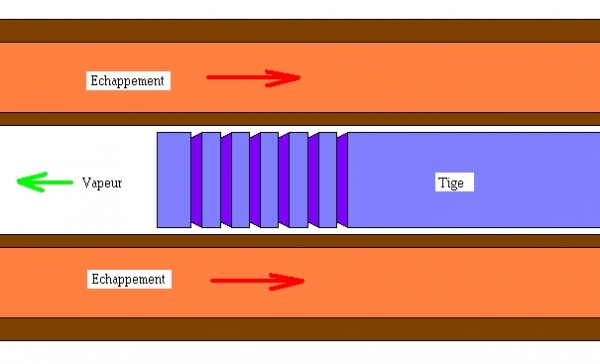

If we consider the reactor as an exchanger, this principle promotes more heat exchange than a cold rod tube.

The Chambrin assembly is still superior.

We know that if we increase the amount of water vapor in the engine we do not increase the economy (apart from the 7-pipe tractor)

We know from Alex's experiments that just steam heated below 100c we have a performance equivalent to mounting the reactor rod.

We know that the outlet temperature of the reactor vapor does not have a direct influence on the output (in my case operating the outlet of the reactor at 110c or 140c little difference on the economy, other on the forum we have low temperatures below 100c and get results.

So you have to look elsewhere for improvement points.

It is not known exactly in what state the vapor, when it is diluted in the intake when entering the engine.

I doubt that such a small amount of vapor in contact with a large volume of air drawn in by the diesel can keep its temperature and are in state during the compression cycle.

A 3-liter downstream engine per 100km 1 k of water for 250 kg of air

a kilo of steam even at 200c will not influence the 250kg of air at room temperature.

What is constant in our experiences which all have variations is fairly identical results

same water consumption (10% to 15% of the fuel consumed)

Same yield around 30% for operational systems

I haven't heard anyone approach 40% on an automobile.

Remain to prove the assembly VIX if one reaches the same figures (quantity of water and economy)

If the perfect heat exchanger assembly improves the system, this would mean that a long rod should improve the system (which is not the case) any more than an exaggerated stove at the inlet of the reactor.

On a 100% panton assembly, a long rod which leaves the reactor is less efficient than a rod which ends abruptly in the heated zone.

I never thought of the reactor as a heat exchanger

each time I used very conductive materials like copper or aluminum the yield decreased

A rod in high carbon steel, or stainless steel is preferable.

we see that it is a material that is a poor conductor of heat?

I saw a guy who pantonized his mower with a reactor made ala goes quickly to test (it was a long time ago) there was nothing right the central rod even touched the tube it worked super well. three months later the guy built another one but tip top pile pile.

guess what? the mower worked less well and consumed more.

A rough unpolished rod, simply deposited in the reactor without centering pins, or any fixing, works as well

just a spring at the outlet to prevent it from sucking

When I was testing all kinds of rod material this is how I proceeded, cut a piece of rod or tube and inside

Andre