re

I forgot to say also agree with chatelot, on the refractory concrete.

It is less good driver than almost all metals, and therefore he has no justification when he is placed in the fumes

but it is justified, when it is in direct contact with the home, because it diffuses the heat and it avoids the hot spots 1000 / 1300 ° C which are destructive for a steel recuperator, that is why the direct recuperators focus are out of cast iron (casting in sand mold often) and not in welded steel.

swallowtail

Heat recovery on a stove with wood (optimization)

-

swallowtail

- I understand econologic

- posts: 77

- Registration: 25/01/09, 00:11

-

the middle

- Econologue expert

- posts: 4075

- Registration: 12/01/07, 08:18

- x 4

Brick stores well in a mass stove because it takes heat directly in the home high temperature: high temperature allows to get heat into the mass of brick ... despite their low conductivity and low conductivity this leaves heat out gently

for a heat recuperator of the smoke I find the brick much less interesting because there is no temperature strong enough to bring the heat in.

Precisely, there you are in error, no need for high temperatures, to raise the temperature of the bricks to 60 degrees, as a mass pile does; it only takes a long heating time. My stove heats all day, in slow motion, the bricks rise to 60 degrees, like a mass poel, and restore the heat at night. (the goal being that the house's temperature does not drop too much at night, when the stove is off)

It's so true that when I bought my poel, I could buy steatite decoration walls, out, these walls are not in direct contact with the hearth

but why the recuperateur store heat, which is a low temperature dificult a store?

Precisely, it is not difficult to store.

This is the mistake not to commit:why change a stove for trnasformer in boiler? why not recover a small oil fired boiler and turn it into a wood boiler?

The fireplace must be as warm as possible, that's why 4 of the walls of my stove are vermiculite, which return the heat on the wood, to raise the gas temperature as high as possible.

in the past, I had a stove with a boiler, the walls were made of sheet metal, with water all around; it was a catastrophe from a combustion point of view, with a huge production of tars.

On the other hand, I have a colleague of office who has a poel, with recuperator in exit of poel, which makes it possible to heat its radiators in the rooms. He is very happy with it, but that is another subject because there is no accumulation.

I must go to see this poel, because he has not cleaned his recuperator all winter.

Chatelot, my goal is not to contradict you, but to give the reality, based on my long personal experience in this field.

For example, my first refractory bricks collector had two layers of bricks; Well, they did not warm up.

If I advise this system is that I'm sure of myself, and I invite all interested to come to see me, he will not be disappointed

0 x

Man is by nature a political animal (Aristotle)

- chatelot16

- Econologue expert

- posts: 6960

- Registration: 11/11/07, 17:33

- Location: Angouleme

- x 264

lejustemilieu wrote:The fireplace must be as warm as possible, that's why 4 of the walls of my stove are vermiculite, which return the heat on the wood, to raise the gas temperature as high as possible.

in the past, I had a stove with a boiler, the walls were made of sheet metal, with water all around; it was a catastrophe from a combustion point of view, with a huge production of tars.

fully agree ! my way of transforming a fuel boiler into a wood-fired boiler, is to lay brick inside against the wall to keep the fireplace warm enough, and not to over-cool it like the boiler cooker

0 x

thank you for your different remarks,

indeed I thought to use the coil embedded in refractory cement just to use the storage of calories in this material may not be as conductive as copper but which keeps heat + for a long time, especially when it is with other refractory bricks. the fact of putting it "in the middle" in my diagram is that it would be "licked" by the hot smoke 200 to 300 ° C (I soon have my super t ° C probe) 2 times before entering the duct .

I think that when the mass of bricks is hot it stays for a long time, and it is a + to recover heat.

one advantage is that we can give it the shape we want by molding it, well ... in + I thought to give it the thickness of bricks, to replace them with bricks in case it is not is not effective ..

now, I know that I will perhaps try casting cast-in-molded serpentine in the middle of the fumes and the mass of bricks, but especially at the outlet of the stove before this mass, around the 160 diameter coupling which heats up extremely, making at least 2 Copper passes around, and isolated.

I thought to make contact between the stove outlet connection and the coil put refractory putty-paste, but I do not know if it holds the copper or the dilations, I imagine that yes since it is refractory ....

I also think that the copper coil will make tars and bistre inside the stove outlet fitting, it will sweep but it is nothing compared to heat gain, and I hope to minimize them by keeping the coil in a loop to t ° C as does Flow-Box boxes (rise in t ° C of the loop, then opening to the rest of the circuit, like the calorstat of a car)

indeed I thought to use the coil embedded in refractory cement just to use the storage of calories in this material may not be as conductive as copper but which keeps heat + for a long time, especially when it is with other refractory bricks. the fact of putting it "in the middle" in my diagram is that it would be "licked" by the hot smoke 200 to 300 ° C (I soon have my super t ° C probe) 2 times before entering the duct .

I think that when the mass of bricks is hot it stays for a long time, and it is a + to recover heat.

one advantage is that we can give it the shape we want by molding it, well ... in + I thought to give it the thickness of bricks, to replace them with bricks in case it is not is not effective ..

now, I know that I will perhaps try casting cast-in-molded serpentine in the middle of the fumes and the mass of bricks, but especially at the outlet of the stove before this mass, around the 160 diameter coupling which heats up extremely, making at least 2 Copper passes around, and isolated.

I thought to make contact between the stove outlet connection and the coil put refractory putty-paste, but I do not know if it holds the copper or the dilations, I imagine that yes since it is refractory ....

I also think that the copper coil will make tars and bistre inside the stove outlet fitting, it will sweep but it is nothing compared to heat gain, and I hope to minimize them by keeping the coil in a loop to t ° C as does Flow-Box boxes (rise in t ° C of the loop, then opening to the rest of the circuit, like the calorstat of a car)

0 x

The bistre (mixture of particles and water) appears on the cold parts whose temperature is lower than 60 °.

This is why the pellet boilers or the "good" log boilers have a system for raising the return temperature, to keep it above 60 °.

Under these conditions, it is a "felting" of particles that is deposited, easily cleanable ...

The relief, when it is not integrated, is carried out by a loop with a 3-way valve "calibrated" at 60 ° ... If the water in the loop has not reached 60 °, it turns " in a ring". When the temperature exceeds 60 °, hot water is released (and this causes a return of cold water)

http://www.aaenergy.fr/pdf/aae_TermovarValve.pdf

This is why the pellet boilers or the "good" log boilers have a system for raising the return temperature, to keep it above 60 °.

Under these conditions, it is a "felting" of particles that is deposited, easily cleanable ...

The relief, when it is not integrated, is carried out by a loop with a 3-way valve "calibrated" at 60 ° ... If the water in the loop has not reached 60 °, it turns " in a ring". When the temperature exceeds 60 °, hot water is released (and this causes a return of cold water)

http://www.aaenergy.fr/pdf/aae_TermovarValve.pdf

0 x

I thank you, so I need a termovar 60 ° C.

it also exists in adjustable? I was thinking "thermostatic valve", like a thermostatic valve, does it?

if not termovar it takes another name in DIY stores, it exists?

on the internet, a good site? =)

I need a circulator too, which does not consume a lot so much as to do;

it also exists in adjustable? I was thinking "thermostatic valve", like a thermostatic valve, does it?

if not termovar it takes another name in DIY stores, it exists?

on the internet, a good site? =)

I need a circulator too, which does not consume a lot so much as to do;

0 x

Yes, just look for an adjustable 3 Valve in any pickup store. And then you mount a circulator, according to the diagram ... Just do not get bogged down in mounting sense!

I recommend a "high performance" circulator with permanent magnets: circulators are undoubtedly quite large electrical consumers in a house, because they run for thousands of hours!

I recommend a "high performance" circulator with permanent magnets: circulators are undoubtedly quite large electrical consumers in a house, because they run for thousands of hours!

0 x

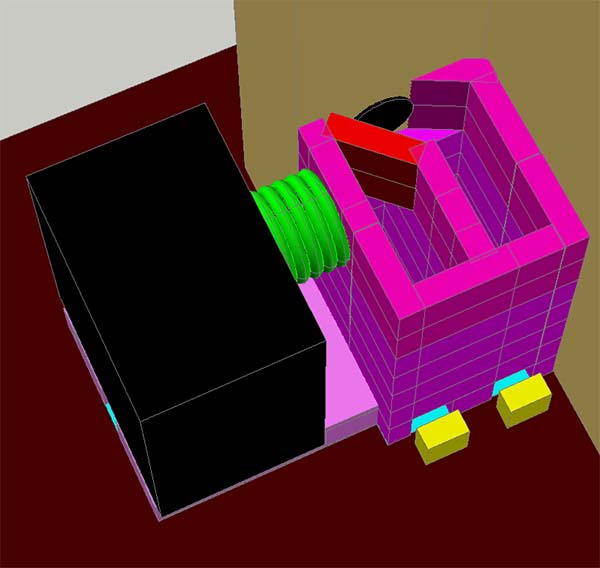

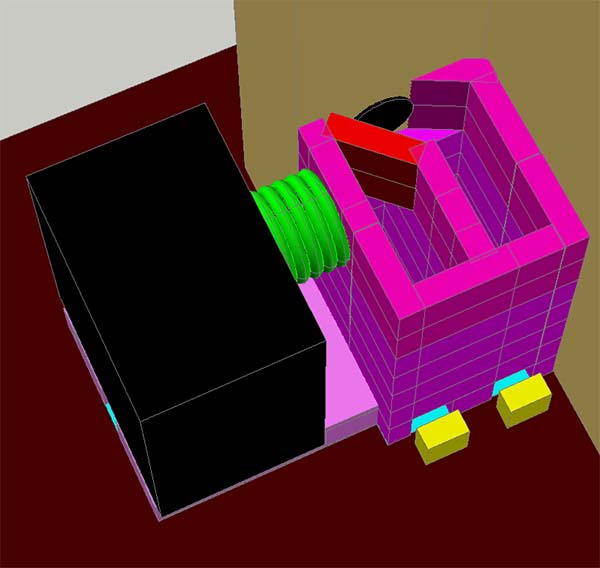

good, doing the project again would give this:

I put the mass of refractory bricks on the side of the duct rather than in front, it takes less space so we can stay in front of the chair =)

in red the inclined part of the duct, which is also by-pass, in yellow the sweeping and in green the copper coil (doubled on itself, about 15m of 14 / 16, isolated).

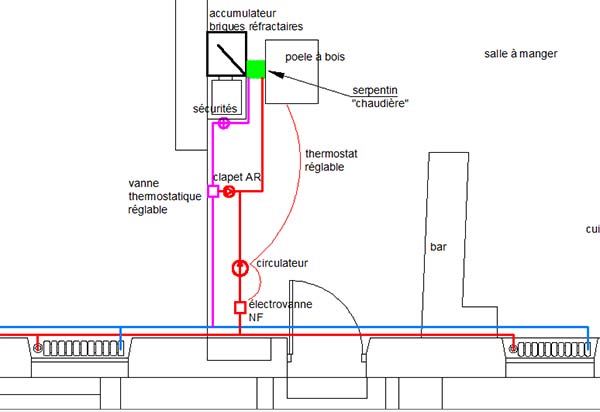

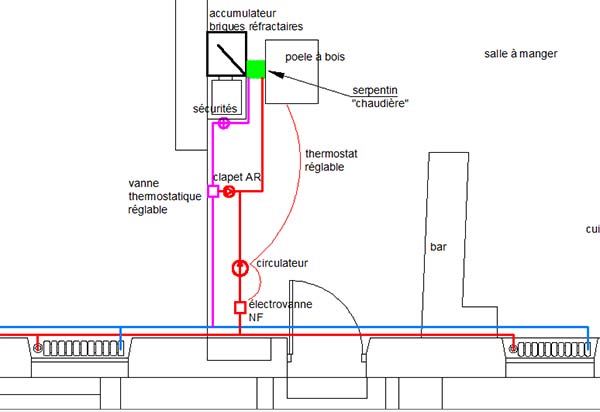

for the water circuit, I thought of a circuit of this type:

so it would run in a loop until it was at 60 ° C, then open on the rest of the circuit; the circulator is on aquastat in the coil loop as well, as well as on the flue gas thermostat (does not work if flue gas t ° C <60 ° C).

but my circuit does not look like the original "Flow box" circuit:

the termovar is not in the same place, nor the non-return valve ...

What do you think ?

here he is like me:

PS: Ouch 630 € TTC, must I get all that separately ...

http://www.distriplomberie.fr/kit-de-ra ... 25-40.html

I put the mass of refractory bricks on the side of the duct rather than in front, it takes less space so we can stay in front of the chair =)

in red the inclined part of the duct, which is also by-pass, in yellow the sweeping and in green the copper coil (doubled on itself, about 15m of 14 / 16, isolated).

for the water circuit, I thought of a circuit of this type:

so it would run in a loop until it was at 60 ° C, then open on the rest of the circuit; the circulator is on aquastat in the coil loop as well, as well as on the flue gas thermostat (does not work if flue gas t ° C <60 ° C).

but my circuit does not look like the original "Flow box" circuit:

the termovar is not in the same place, nor the non-return valve ...

What do you think ?

here he is like me:

PS: Ouch 630 € TTC, must I get all that separately ...

http://www.distriplomberie.fr/kit-de-ra ... 25-40.html

0 x

250 €:

http://sespdistribution.com/wilo/171-ki ... voies.html

on the other hand it is not a thermostatic valve type thermovar, it is an adjustable valve for floor heating ...

http://sespdistribution.com/wilo/171-ki ... voies.html

on the other hand it is not a thermostatic valve type thermovar, it is an adjustable valve for floor heating ...

0 x

apparently the thermovar can be replaced by an adjustable thermostatic valve,

I don't know if we can use a "temperature limiter" 50 € leroy merlin:

http://www.leroymerlin.fr/v3/p/produits ... ure-e56658

see a thermostatic radiator valve € 30, mounted on a "T"?

http://www.leroymerlin.fr/v3/p/produits ... ue&xtcr=16

it's good for that, no?

good at 100 € the termovar ... will have to look on ebay.de ... or to recover the system of heat of a car! =) with probe incorporated of course; =)

otherwise my connection diagram on an existing installation, without connecting to the boiler but "anywhere" on the heating circuit looks like this, if that helps:

should it hold up?

I don't know if we can use a "temperature limiter" 50 € leroy merlin:

http://www.leroymerlin.fr/v3/p/produits ... ure-e56658

see a thermostatic radiator valve € 30, mounted on a "T"?

http://www.leroymerlin.fr/v3/p/produits ... ue&xtcr=16

it's good for that, no?

good at 100 € the termovar ... will have to look on ebay.de ... or to recover the system of heat of a car! =) with probe incorporated of course; =)

otherwise my connection diagram on an existing installation, without connecting to the boiler but "anywhere" on the heating circuit looks like this, if that helps:

should it hold up?

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 5 Replies

- 1348 views

-

Last message by sicetaitsimple

View the latest post

20/10/23, 21:15A subject posted in the forum : Heating, insulation, ventilation, VMC, cooling ...

-

- 25 Replies

- 4092 views

-

Last message by Macro

View the latest post

22/12/22, 12:51A subject posted in the forum : Heating, insulation, ventilation, VMC, cooling ...

-

- 7 Replies

- 2067 views

-

Last message by phil59

View the latest post

23/11/22, 15:56A subject posted in the forum : Heating, insulation, ventilation, VMC, cooling ...

-

- 1 Replies

- 10896 views

-

Last message by Arnaud M

View the latest post

11/02/11, 10:08A subject posted in the forum : Heating, insulation, ventilation, VMC, cooling ...

-

- 3 Replies

- 5038 views

-

Last message by Sunflower

View the latest post

18/07/10, 20:46A subject posted in the forum : Heating, insulation, ventilation, VMC, cooling ...

Back to "Heating, insulation, ventilation, VMC, cooling ..."

Who is online ?

Users browsing this forum : Google Adsense [Bot] and 333 guests