Unpublished production of miscanthus straw wood pellets

Unpublished production of miscanthus straw wood pellets

Message deleted by the author

Last edited by stefff the 05 / 04 / 12, 17: 55, 1 edited once.

0 x

without prejudging the perhaps great process that you have implemented, only part of the energy necessary for the manufacture of wood pellets is used for the press.

it is also necessary grinding / calibration and especially drying (which is done on the basis of pellet heating, it is true)

the quality and consistency of the final product depends very much on the quality of the sawdust as input. it is also the interest of large volumes compared to a small production: the variations are smoothed.

there are already small low-power presses like the one below

it is also necessary grinding / calibration and especially drying (which is done on the basis of pellet heating, it is true)

the quality and consistency of the final product depends very much on the quality of the sawdust as input. it is also the interest of large volumes compared to a small production: the variations are smoothed.

there are already small low-power presses like the one below

0 x

Production of pellets at cost

What slows down the development of production lines for sawdust pellets, etc. is the cost of the investment. Drying included.

Can you tell us the price for a small and medium production line. Thank you

Can you tell us the price for a small and medium production line. Thank you

0 x

-

Christophe

- Moderator

- posts: 79295

- Registration: 10/02/03, 14:06

- Location: Greenhouse planet

- x 11028

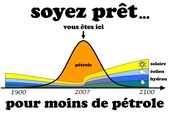

The energy costs of drying and grinding are high but are not that important, less than the costs of refining fuel oil for example.

Here are the numbers: gray energy from pellets and other petroleum fuels

Here are the numbers: gray energy from pellets and other petroleum fuels

Last edited by Christophe the 27 / 04 / 09, 11: 11, 1 edited once.

0 x

Do a image search or an text search - Netiquette of forum

- Capt_Maloche

- Moderator

- posts: 4559

- Registration: 29/07/06, 11:14

- Location: Ile-de-France

- x 42

Besides, it's not easy to produce a clean granule

Isn't there too much dust coming off?

There is a sector which is developing strongly in our regions, it is called CALYS:

https://www.econologie.info/share/partag ... tP8HUZ.pdf

Isn't there too much dust coming off?

There is a sector which is developing strongly in our regions, it is called CALYS:

Capt_Maloche wrote:

An alternative to wood pellets exists today, usable with the major brands of pellet wood boilers designed with moving bottom fireplaces (Gunter brand for example); this new type of pellet called Agro Pellet is made from locally available vegetable raw materials.

Its undeniable advantage is undoubtedly its annual renewal rate unlike wood, the rate of which will be greater than 20 years. This pellet ensures good quality combustion with no trace of clinker or acidic vapors and has a higher energy balance than wood pellet.

This new TOTALLY RENEWABLE energy source consists of an assembly consisting solely of plant co-products. The concept makes it possible to valorize all kinds of plant residues according to the locality: Broken seeds, silo sorting gaps, non-exploited vegetable matter. This source of material represents today 4000Tonnes annual in the region of Etampes (1% of cereal production)

The agricultural cooperative of Ile de France Sud established in the industrial area of Morigny offers this sector from the beginning of 2009, and will be able to distribute at first more than 500Tons and ultimately 2500Tons of high quality compound pellets, for 60 % grain, 10% oilseed meal, 20/30% oak and beech lumber from sawmills and shavings and a mineral catalyst responsible for eliminating clinker and acid vapors ;

These granules of a new type can be stored in the same silos as the grains, thus allowing the cooperative to ensure a guaranteed stock of 6 months of combustible material at a price lower than wood pellets and at a cost 2 times less than domestic fuel oil.

https://www.econologie.info/share/partag ... tP8HUZ.pdf

Diet

The feed hoppers are used to empty the

contents of a big-bag or a small bucket.

They are equipped with:

• a dynamic devourer allowing a perfect

flow of matter;

• a protective grid;

• a recovery screw located under the hopper, ensuring

the extraction of the material.

The incorporation of additive

A special hopper allows to incorporate and

metering additives very precisely

in powder form.

Weighing - dosing

Upon entry of products into the Compact Unit of

Granulation, they are weighed continuously. This allows

precisely define the proportion

of each raw material.

Grinding

A pre-grinder followed by a hammer mill (refiner) allows

reduce the grain size:

• the pre-shredder breaks up coarse elements

(lumps, dumplings, chips);

• the refiner is fitted with hammers (steel blades) which strike

and explode the material and force it to pass through a grid

made of perforated sheet. The material is reduced to the state of flour

in order to give the final granule an impeccable appearance.

The mixture

• The ribbon mixer performs the mixing

different raw materials.

• A spray of water makes it possible to correct, if necessary,

humidity of the product.

• The mixture is then transferred by equipment

handling (elevator and Archimedes screw) to the unit

granulation.

Granulation

The presses do the job of

compaction of matter by forcing it

through the compression channels

of the industry.

The presses do this job thanks to

two compression rollers.

The volume of the material is reduced by 4 and the

granules obtained have a temperature

around 100 ° C.

The recooling

Cooling involves passing from

room temperature air in the bed

granules.

The horizontally circulating air absorbs the

heat contained in the granules, on contact

fresh air these cool.

The sieve placed below the cooler

remove fines before storage or

bagging granules.

0 x

"Consumption is similar to a search consolation, a way to fill a growing existential void. With, the key, a lot of frustration and a little guilt, increasing the environmental awareness." (Gérard Mermet)

OUCH, OUILLE, OUCH, AAHH! ^ _ ^

OUCH, OUILLE, OUCH, AAHH! ^ _ ^

-

Christophe

- Moderator

- posts: 79295

- Registration: 10/02/03, 14:06

- Location: Greenhouse planet

- x 11028

Capt_Maloche wrote:Besides, it's not easy to produce a clean granule

Isn't there too much dust coming off?

It is included in the standards, it is called "durability" (if it is not invented):

https://www.econologie.com/proprietes-de ... -3623.html

https://www.econologie.com/biocombustibl ... -3622.html

a) For pellets intended for individuals

- Origin: wood not chemically treated.

- Humidity: M08 (<8% relative).

- Durability: DU97,5 (which means that after sieving, see "Find out more", 97,5% or more of the pellets must remain intact).

- Diameter: D06 or D08 (6 or 8 mm).

- Length: <4 or 5 times the diameter, i.e. 30 mm maximum for D06.

- Ash content: <A0,5 (<0,5% volume)

- Sulfur: <S0,02

- Nitrogen: <N0,3

- Close: <Cl0,01

- PCI:> = Q16.9 (i.e. 16.9 MJ / kg or 4,69 kWh / kg)

- Bulk density MMV: BD650 (> 650 kg / m3)

0 x

Do a image search or an text search - Netiquette of forum

-

the middle

- Econologue expert

- posts: 4075

- Registration: 12/01/07, 08:18

- x 4

Hello Stefff,

In Belgium, we are interested in your grass,

Take a look here: (keyword: Valbion- Miscanthus)

They have a lab too, it seems.

http://agriculture.wallonie.be/apps/spi ... ontres.pdf

In Belgium, we are interested in your grass,

Take a look here: (keyword: Valbion- Miscanthus)

They have a lab too, it seems.

http://agriculture.wallonie.be/apps/spi ... ontres.pdf

0 x

Man is by nature a political animal (Aristotle)

-

Christophe

- Moderator

- posts: 79295

- Registration: 10/02/03, 14:06

- Location: Greenhouse planet

- x 11028

lejustemilieu wrote:In Belgium, we are interested in your grass,

I confirm! I even have a plant in the garden that resumes well there, would like one more photo to make this AM!

0 x

Do a image search or an text search - Netiquette of forum

- This company manufactures, among other things, pellet presses or pelletizers and grinders to condition the materials to be pelletized.

- Your entry level starts at 7.5kW in 380V Three-phase.

I already touched on the subject forum, and found, in France, Chinese products that start with machines less than 3kW (at € 600).

My thinking was as follows:

Our bins overflow with combustible materials, many of which invade us against our will (advertisements, packaging, garden waste ...) and we pay (taxes on household waste) to get rid of them.

So I imagined that we could recycle these fuels as it exists with "manual newspaper presses". For having tried such presses, I was able to appreciate the validity of the concept but not that of the product.

Can we therefore consider a compact shredder / pelletizer of less than 3600W in mono 230V (16A) at less than 1500 € TTC.

It remains to define the amount of material necessary to meet these own needs.

0 x

-

- Similar topics

- Replies

- views

- Last message

-

- 0 Replies

- 1662 views

-

Last message by Paul44650

View the latest post

08/06/23, 12:33A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 1 Replies

- 3681 views

-

Last message by yves35

View the latest post

03/10/16, 01:53A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 30 Replies

- 20534 views

-

Last message by moinsdewatt

View the latest post

17/05/15, 13:23A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 19 Replies

- 19554 views

-

Last message by phil59

View the latest post

04/11/23, 18:49A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

-

- 13 Replies

- 22014 views

-

Last message by 1360

View the latest post

14/08/13, 12:47A subject posted in the forum : Hydraulic, wind, geothermal, marine energy, biogas ...

Back to "hydraulic, wind, geothermal, marine energy, biogas ..."

Who is online ?

Users browsing this forum : No registered users and 169 guests