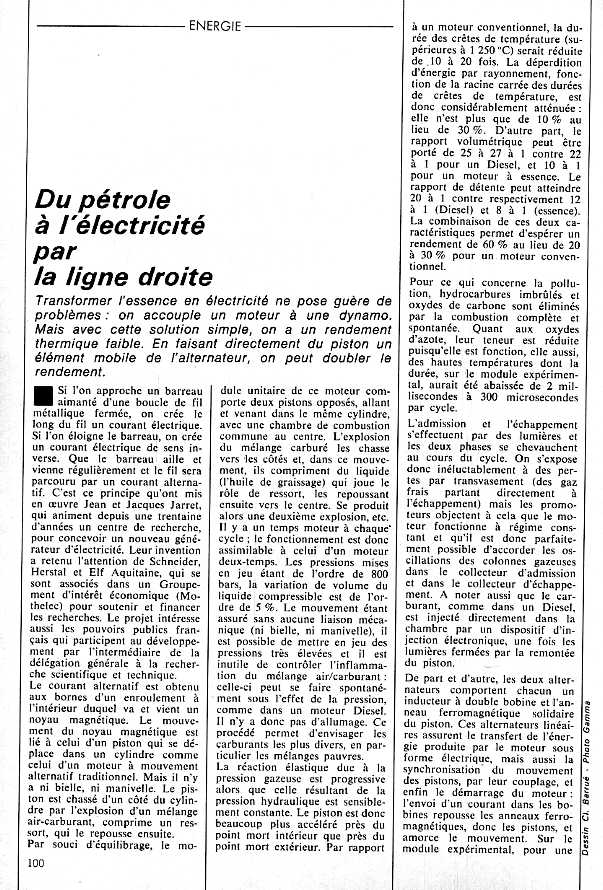

He put the time engine (multi-fuel) at a time ...

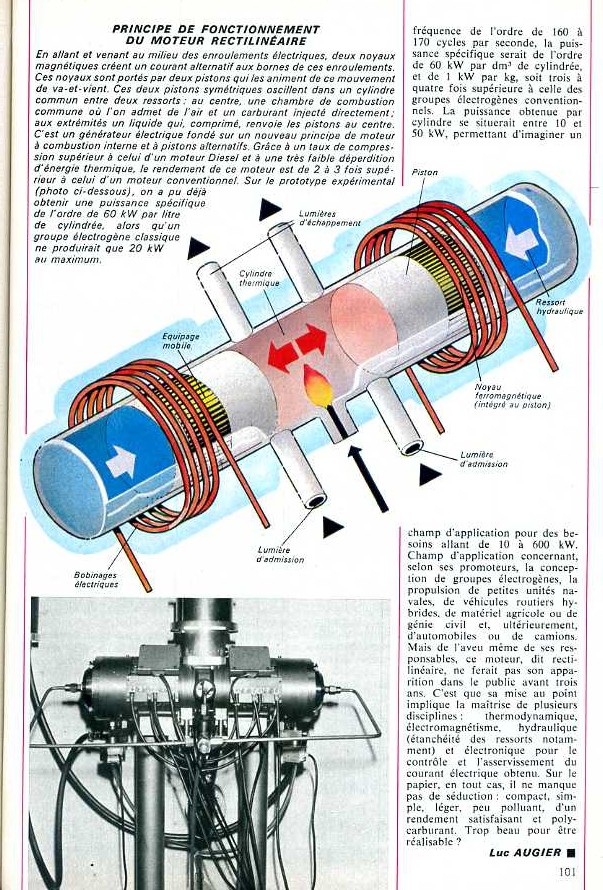

In wizards of annealed bread, a German team designed an internal combustion engine based on the principle of a linear generator with free piston to power the electric motor of a car. A novelty inspired by a patented 1816 engine.

Researchers from the German Aerospace Center (DLR) have produced a new internal combustion engine based on the principle of a linear free-piston generator. This technique, more or less inspired by the stirling engine that has never had the chance to be successful, allows to design an engine capable of transforming any type of fuel (gasoline, natural gas, hydrogen or ethanol) into electrical energy, without the losses of efficiency usually encountered. The crankshaft of a traditional engine is replaced by a linear generator and a pneumatic spring. The generator directly produces electrical energy that can be used to propel a vehicle by means of an electric motor. The compression ratio and engine displacement being variable, its operation in reduced power is highly optimized. This reduces the engine consumption, as well as its polluting emissions, especially when used at low speeds as is the case when traveling in the city. According to researchers, this new engine should be on the market by 5 to 6 years ago.

Let's hope that this good idea will not suffer the same fate as the engine of the brothers Jarret, inspired by the same concept but which never knew the slightest echo, probably for lack of opportunities at a time when the oil seemed inexhaustible. Indeed, if the energy efficiency seems particularly attractive thanks to the absence of unnecessary friction caused by a traditional mechanical cumbersome, it is realized that there is an impressive amount of adjustments to be made before claiming to operate such a motor in the automobile industry.

Et here the original link in German.